MCpcba Separatorpcb depaneler manufactory punch diePCBa routing machine Factory-YSVC-2LL-Features:

The use of the latest gas-powered lightweight design, High-tech delivery facilities, without manual operation, continuous finish without COB Depaneling Machine stress cutting trip, especially for Depaneling precision SMD or sheet. (BOW WAVES) and micro-cracks (MICRO CRACK) generated by the round knife type Depaneling, the use of wedge-shaped tool linear Depaneling, V Depaneling stress to a minimum.

1. Cutting rate of 1 second / 1 split, controlled by the foot pedal pneumatic switch;

2. High-tech delivery facilities, without manual operation;

3. Using microcomputer technology, the program can automatically control the number of cutting and cutting stroke;

Non-roller (knife, knife) type cutting, no dust phenomenon, no motor drive, no toner pollution.

5. Non-friction cutting, no tool metal residue;

6. Blade used up to 300000 / times or more;

7. Tool used in Germany imported high-quality high-speed steel, large-scale professional tool factory in Taiwan custom;

8. Use 4-5KG of air pressure, no specific cutting place; appearance to rust cleaning oil can be wiped;

With automatic counting function;

10. Easy to use, ordinary staff can be a simple guide to operate.

COB Depaneling machine equipment parameters:

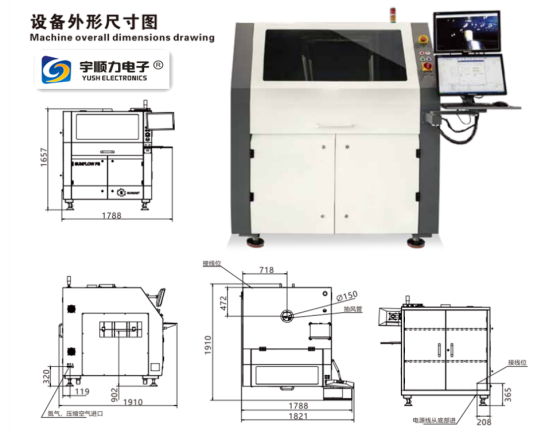

Model: YSVC-2LL

Machine specifications: 428 × 508 × 912mm

Slab thickness: 0.8-3.5mm

Fractional speed: 0-1000mm / s

Maximum slab length: 45cm

Use voltage: 220VAC

Machine weight: 120kg

Depaneling machine: cob light source substrate, bulb LED aluminum plate / ceramic plate, etc., where the V-CUT SMD PCB board can be applied to this machine

MCpcba Separatorpcb depaneler manufactory punch diePCBa routing machine Factory-YSVC-2LL-Features:

The use of the latest gas-powered lightweight design, High-tech delivery facilities, without manual operation, continuous finish without COB Depaneling Machine stress cutting trip, especially for Depaneling precision SMD or sheet. (BOW WAVES) and micro-cracks (MICRO CRACK) generated by the round knife type Depaneling, the use of wedge-shaped tool linear Depaneling, V Depaneling stress to a minimum.

1. Cutting rate of 1 second / 1 split, controlled by the foot pedal pneumatic switch;

2. High-tech delivery facilities, without manual operation;

3. Using microcomputer technology, the program can automatically control the number of cutting and cutting stroke;

Non-roller (knife, knife) type cutting, no dust phenomenon, no motor drive, no toner pollution.

5. Non-friction cutting, no tool metal residue;

6. Blade used up to 300000 / times or more;

7. Tool used in Germany imported high-quality high-speed steel, large-scale professional tool factory in Taiwan custom;

8. Use 4-5KG of air pressure, no specific cutting place; appearance to rust cleaning oil can be wiped;

With automatic counting function;

10. Easy to use, ordinary staff can be a simple guide to operate.

COB Depaneling machine equipment parameters:

Model: YSVC-2LL

Machine specifications: 428 × 508 × 912mm

Slab thickness: 0.8-3.5mm

Fractional speed: 0-1000mm / s

Maximum slab length: 45cm

Use voltage: 220VAC

Machine weight: 120kg

Depaneling machine: cob light source substrate, bulb LED aluminum plate / ceramic plate, etc., where the V-CUT SMD PCB board can be applied to this machine

SMT placement machine placement machine parts placement machine

Dual arm magnetic linear LED highspeed pick and place machine

SMT Machine/ High Professional Customization/ Multi Function SMT Line Automatic Factory in China

Best Selling Heller Reflow Soldering Oven Machine For SMT Machine Line

High Speed 6 Heads Multi-functional SMT Pick and Place Machine LED Automatic

Contacts:Eva Liu +8613450659407 +86 13416743702

Tel:+86-512-62751429

Skype:evaliuhuan

Email: caojun@hk-yush.com sales@yushunli.com evaliu@hk-yush.com

Address: Building H, GuoRui Pioneering Park,

No. 1068 Jinyang East Road, Lujia Town, Kunshan,

Suzhou.

Postcode:215331

Dongguan Factory Address: 5th Floor, No.10, Shanquan Road,

Yongtou Village, Chang’an Town, Dongguan City, Guangdong

province,

China.

Postcode:523843