Features introduced:

1, PCB Cutting Machine for all kinds of PCB boards (for circuit boards with double-sided components)

2, PLC man-machine interface switch, control program by the computer to achieve automatic pneumatic brake PCB Cutting Machine times and PCB Cutting Machine trip, saving workers to improve efficiency.

3, Straight knife up and down to solve double-sided PCBA to achieve PCB Cutting Machine.

4, automatic feeding PCB Cutting Machine, with automatic counting function, visual display output

5, PCB board cutting is completed, through the conveyor belt directly extended to the test assembly line, the workers to avoid secondary operation parts.

6, Electric eye protection device to ensure production safety.

7, PCB Cutting Machine process PCB board does not move, round knife slide, straight knife up and down to ensure that the substrate electronic components are not damaged due to movement.

8, This type of feed for the extended work mode, after the PCB board cut through the conveyor belt can be extended directly to the inspection line.

Specifications:

| Project | Parameters |

| Equipment Brand | YUSHLI |

| Device Name |

Offline Automatic tool depaneling machine |

| Device models | YSV-2L |

| User interface | PLC man-machine interface exchange |

| Languages | Chinese-English |

| Max Cutting length | 350MM |

| Depaneling width | 50 ~ 230mm |

| Depaneling thickness of | 0.3 ~ 3.5MM |

| Component height limit on | 35 MM, 15 MM under |

| Operating voltage | AC 110 ~ 220V 50 / 60HZ |

| Working pressure | 0.6-0.8MP |

| Blade material | Imported SKD61 high-speed steel |

| Appearance | Paint white (other colors can be customized) |

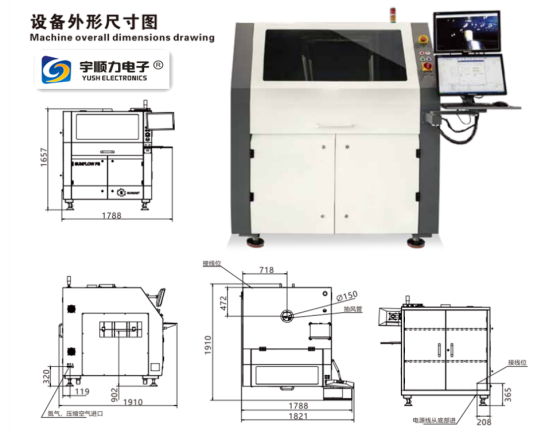

| Dimensions | L1020 * W650 * H600 MM |

| Safety devices | Electric eye safety device |

|

Working temperature: |

10-50 ℃ |

|

Storage temperature: |

-20-50 ℃ |

|

Weight |

86KG |

Features introduced:

1, PCB Cutting Machine for all kinds of PCB boards (for circuit boards with double-sided components)

2, PLC man-machine interface switch, control program by the computer to achieve automatic pneumatic brake PCB Cutting Machine times and PCB Cutting Machine trip, saving workers to improve efficiency.

3, Straight knife up and down to solve double-sided PCBA to achieve PCB Cutting Machine.

4, automatic feeding PCB Cutting Machine, with automatic counting function, visual display output

5, PCB board cutting is completed, through the conveyor belt directly extended to the test assembly line, the workers to avoid secondary operation parts.

6, Electric eye protection device to ensure production safety.

7, PCB Cutting Machine process PCB board does not move, round knife slide, straight knife up and down to ensure that the substrate electronic components are not damaged due to movement.

8, This type of feed for the extended work mode, after the PCB board cut through the conveyor belt can be extended directly to the inspection line.

Specifications:

| Project | Parameters |

| Equipment Brand | YUSHLI |

| Device Name |

Offline Automatic tool depaneling machine |

| Device models | YSV-2L |

| User interface | PLC man-machine interface exchange |

| Languages | Chinese-English |

| Max Cutting length | 350MM |

| Depaneling width | 50 ~ 230mm |

| Depaneling thickness of | 0.3 ~ 3.5MM |

| Component height limit on | 35 MM, 15 MM under |

| Operating voltage | AC 110 ~ 220V 50 / 60HZ |

| Working pressure | 0.6-0.8MP |

| Blade material | Imported SKD61 high-speed steel |

| Appearance | Paint white (other colors can be customized) |

| Dimensions | L1020 * W650 * H600 MM |

| Safety devices | Electric eye safety device |

|

Working temperature: |

10-50 ℃ |

|

Storage temperature: |

-20-50 ℃ |

|

Weight |

86KG |

SMT placement machine placement machine parts placement machine

Dual arm magnetic linear LED highspeed pick and place machine

SMT Machine/ High Professional Customization/ Multi Function SMT Line Automatic Factory in China

Best Selling Heller Reflow Soldering Oven Machine For SMT Machine Line

High Speed 6 Heads Multi-functional SMT Pick and Place Machine LED Automatic

Contacts:Eva Liu +8613450659407 +86 13416743702

Tel:+86-512-62751429

Skype:evaliuhuan

Email: caojun@hk-yush.com sales@yushunli.com evaliu@hk-yush.com

Address: Building H, GuoRui Pioneering Park,

No. 1068 Jinyang East Road, Lujia Town, Kunshan,

Suzhou.

Postcode:215331

Dongguan Factory Address: 5th Floor, No.10, Shanquan Road,

Yongtou Village, Chang’an Town, Dongguan City, Guangdong

province,

China.

Postcode:523843