1. equipment introduction

Flex PCB Circuit Automatic depaneling is an automated depaneling device developed and patented by Suzhou Yu Shun Li Electronics Co., Ltd. based on the needs of the T8LEDFlex light belt on the market today. It is targeted at the Flex PCB Circuit of the Flex PCB Circuit circuit board Depressed, according to the width of the customer requirements of the width of the board width of the full-page cutting, the cutting effect is good, fast, much customer-friendly; for different sizes and specifications of the LEDFlex PCB Circuit products; to solve the customer manual depaneling slow, cutting poor results problem;

Features:

1, for Flex light belt, Flex PCB circuit, Flex light bar circuit board LEDFlex light belt, Flex PCB Circuit, Flex light bar for cutting;

2, manually adjust the cutting blade module level, to solve the Flex PCB circuit thickness of the problem;

3, v cut with V groove guide to ensure product quality;

4, high efficiency: Vmax = 400mm / s, and the speed adjustable;

5, high precision, easy maintenance, high security;

6, the machine is simple, easy to use, solid and durable;

7, cutting mode lifting range: 25mm;

8, for different width of the Flex PCB Circuit, only need to replace the knife and fixture can be, easy to adjust;

9, cutting mode using left and right recycling, improve cutting efficiency;

Main configuration:

|

Configuration name |

unit |

Quantity |

Remarks |

|

Drive motor |

set |

2 |

Reese step |

|

Screw guide |

set |

3 |

Taiwan HIWIN |

|

Pilot cylinder |

set |

5 |

Star Pneumatic |

|

man - machine interface |

set |

1 |

Taiwan Weilun |

|

Industrial control system |

station |

1 |

Industrial PLC |

|

cutting Knife mold |

set |

1 |

Imported tungsten steel mold |

|

Control software |

set |

1 |

Pinyao-auto |

|

Timing belt |

set |

1 |

Import mute timing belt |

|

The electromagnetic valve |

set |

3 |

Yade off |

|

Switching power supply |

set |

1 |

Taiwan Mingwei |

|

air filter |

One |

1 |

Brave Pneumatic |

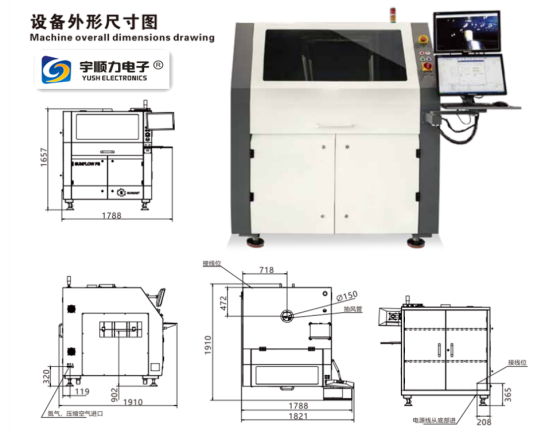

2. technical parameters

|

Equipment model |

YSVC-1200 |

YSVC-1500 |

|

length |

1200mm |

1500mm |

|

speed |

500mm/sec |

|

|

Repeat accuracy |

±0.02mm |

|

|

Resolution |

0.01mm |

|

|

operating system |

PLC + man - machine interface |

|

|

transfer method |

Precision stepper motor + synchronous technology |

|

|

Cutting mode |

High precision rotating tungsten steel |

|

|

Targeting |

Positioning fixture + cylinder in place |

|

|

Working power supply |

AC220V 50-60HZ 1.0KW |

|

|

Machine size |

1350╳950╳1120mm |

1650╳950╳1120mm |

|

equipment weight |

350KG |

450KG |

1. equipment introduction

Flex PCB Circuit Automatic depaneling is an automated depaneling device developed and patented by Suzhou Yu Shun Li Electronics Co., Ltd. based on the needs of the T8LEDFlex light belt on the market today. It is targeted at the Flex PCB Circuit of the Flex PCB Circuit circuit board Depressed, according to the width of the customer requirements of the width of the board width of the full-page cutting, the cutting effect is good, fast, much customer-friendly; for different sizes and specifications of the LEDFlex PCB Circuit products; to solve the customer manual depaneling slow, cutting poor results problem;

Features:

1, for Flex light belt, Flex PCB circuit, Flex light bar circuit board LEDFlex light belt, Flex PCB Circuit, Flex light bar for cutting;

2, manually adjust the cutting blade module level, to solve the Flex PCB circuit thickness of the problem;

3, v cut with V groove guide to ensure product quality;

4, high efficiency: Vmax = 400mm / s, and the speed adjustable;

5, high precision, easy maintenance, high security;

6, the machine is simple, easy to use, solid and durable;

7, cutting mode lifting range: 25mm;

8, for different width of the Flex PCB Circuit, only need to replace the knife and fixture can be, easy to adjust;

9, cutting mode using left and right recycling, improve cutting efficiency;

Main configuration:

|

Configuration name |

unit |

Quantity |

Remarks |

|

Drive motor |

set |

2 |

Reese step |

|

Screw guide |

set |

3 |

Taiwan HIWIN |

|

Pilot cylinder |

set |

5 |

Star Pneumatic |

|

man - machine interface |

set |

1 |

Taiwan Weilun |

|

Industrial control system |

station |

1 |

Industrial PLC |

|

cutting Knife mold |

set |

1 |

Imported tungsten steel mold |

|

Control software |

set |

1 |

Pinyao-auto |

|

Timing belt |

set |

1 |

Import mute timing belt |

|

The electromagnetic valve |

set |

3 |

Yade off |

|

Switching power supply |

set |

1 |

Taiwan Mingwei |

|

air filter |

One |

1 |

Brave Pneumatic |

2. technical parameters

|

Equipment model |

YSVC-1200 |

YSVC-1500 |

|

length |

1200mm |

1500mm |

|

speed |

500mm/sec |

|

|

Repeat accuracy |

±0.02mm |

|

|

Resolution |

0.01mm |

|

|

operating system |

PLC + man - machine interface |

|

|

transfer method |

Precision stepper motor + synchronous technology |

|

|

Cutting mode |

High precision rotating tungsten steel |

|

|

Targeting |

Positioning fixture + cylinder in place |

|

|

Working power supply |

AC220V 50-60HZ 1.0KW |

|

|

Machine size |

1350╳950╳1120mm |

1650╳950╳1120mm |

|

equipment weight |

350KG |

450KG |

SMT placement machine placement machine parts placement machine

Dual arm magnetic linear LED highspeed pick and place machine

SMT Machine/ High Professional Customization/ Multi Function SMT Line Automatic Factory in China

Best Selling Heller Reflow Soldering Oven Machine For SMT Machine Line

High Speed 6 Heads Multi-functional SMT Pick and Place Machine LED Automatic

Contacts:Eva Liu +8613450659407 +86 13416743702

Tel:+86-512-62751429

Skype:evaliuhuan

Email: caojun@hk-yush.com sales@yushunli.com evaliu@hk-yush.com

Address: Building H, GuoRui Pioneering Park,

No. 1068 Jinyang East Road, Lujia Town, Kunshan,

Suzhou.

Postcode:215331

Dongguan Factory Address: 5th Floor, No.10, Shanquan Road,

Yongtou Village, Chang’an Town, Dongguan City, Guangdong

province,

China.

Postcode:523843