Quick Details:

cooling-down method:

hydrocooling

control method:

voluntarily

Usage:

pulse heat

Certification:

ce

Weight:

35KG

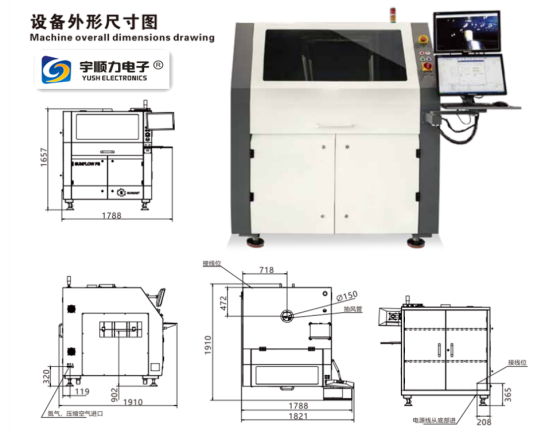

Dimensions:

430*185*220

Current:

2000DCA

Rated Capacity:

10KW

Voltage:

220V

Rated Duty Cycle:

10

Model Number:

YSPDY

Place of Origin:

Guangdong, China (Mainland)

Condition:

New

Type:

Soldering Machine

Hot bar welding machine for mobile phone wire

Brief introduction to welding process of precision pulse hot welding:

Simply put, this process is the two pre good flux, tin plated parts heating to the temperature of melting solder (lead-free solder melting point: 217 DEG C), solidification, a permanent electrical machinery connects the two parts formed by curing solder.

Those who can not use the SMT welding device + reflow oven, which we can use for constant temperature soldering iron hand welding, manual welding welding appearance but prone to inconsistent, uneven, and even weld or welding defects such as bad products. And the precision pulse hot press is different from the constant temperature soldering iron, precision pulse hot press power instantly the desired temperature is reached, and once the head ends without voltage, instantaneous air-cooled can reach room temperature, and the pressure head flat, welding out the appearance of the product but also smooth.

Principle of precision inverting DC hot welding:

The hot head loaded on a certain pulse voltage with low voltage and high current, the hot head heating high impedance, will be in contact with the body temperature when the temperature rise to the solder! The melting point of two objects in contact with the weld together. The control pulse heating is by welding in pressure the first part of the heating thermocouple temperature detection and real-time feedback to the temperature controller for the closed-loop control to achieve.

operation chart

Mobile phone charging line /PCB and copper PIN foot / soft cable, /FPC flexible paper / zebra paper YSPDY series precision hot welding machine example:

An analysis of welding samples: the workpiece is AFC soft wire welding to the PCB board, PCB board pre brush tin solder joint, one-time welding and welding firm, tin climb proofing uniform full. The horn size is a little bigger, so the pressure to go above the zebra paper leads to solder joint around the zebra paper with slight melting temperature control, hot pressure welding machine our accurate heat concentrated, there is no effect on the solder joints surrounding, only need to post production of small horn size does not appear the case.

Other similar examples of welding sample map:

our services:

1. We are the leading precise welding company, and can help you detect a

best precise welding plan with our more than 20 years welding

experience.

2. We can design and develop precise welding machine according your requirements.

3. We can help you welding some samples for testing before you buy the machine, and it is free.

4. We are usually punctual and trustworthy.

5. We want to meet the best costmer’s satisfaction so that we can won more chanc

Quick Details:

cooling-down method:

hydrocooling

control method:

voluntarily

Usage:

pulse heat

Certification:

ce

Weight:

35KG

Dimensions:

430*185*220

Current:

2000DCA

Rated Capacity:

10KW

Voltage:

220V

Rated Duty Cycle:

10

Model Number:

YSPDY

Place of Origin:

Guangdong, China (Mainland)

Condition:

New

Type:

Soldering Machine

Hot bar welding machine for mobile phone wire

Brief introduction to welding process of precision pulse hot welding:

Simply put, this process is the two pre good flux, tin plated parts heating to the temperature of melting solder (lead-free solder melting point: 217 DEG C), solidification, a permanent electrical machinery connects the two parts formed by curing solder.

Those who can not use the SMT welding device + reflow oven, which we can use for constant temperature soldering iron hand welding, manual welding welding appearance but prone to inconsistent, uneven, and even weld or welding defects such as bad products. And the precision pulse hot press is different from the constant temperature soldering iron, precision pulse hot press power instantly the desired temperature is reached, and once the head ends without voltage, instantaneous air-cooled can reach room temperature, and the pressure head flat, welding out the appearance of the product but also smooth.

Principle of precision inverting DC hot welding:

The hot head loaded on a certain pulse voltage with low voltage and high current, the hot head heating high impedance, will be in contact with the body temperature when the temperature rise to the solder! The melting point of two objects in contact with the weld together. The control pulse heating is by welding in pressure the first part of the heating thermocouple temperature detection and real-time feedback to the temperature controller for the closed-loop control to achieve.

operation chart

Mobile phone charging line /PCB and copper PIN foot / soft cable, /FPC flexible paper / zebra paper YSPDY series precision hot welding machine example:

An analysis of welding samples: the workpiece is AFC soft wire welding to the PCB board, PCB board pre brush tin solder joint, one-time welding and welding firm, tin climb proofing uniform full. The horn size is a little bigger, so the pressure to go above the zebra paper leads to solder joint around the zebra paper with slight melting temperature control, hot pressure welding machine our accurate heat concentrated, there is no effect on the solder joints surrounding, only need to post production of small horn size does not appear the case.

Other similar examples of welding sample map:

our services:

1. We are the leading precise welding company, and can help you detect a

best precise welding plan with our more than 20 years welding

experience.

2. We can design and develop precise welding machine according your requirements.

3. We can help you welding some samples for testing before you buy the machine, and it is free.

4. We are usually punctual and trustworthy.

5. We want to meet the best costmer’s satisfaction so that we can won more chanc

SMT placement machine placement machine parts placement machine

Dual arm magnetic linear LED highspeed pick and place machine

SMT Machine/ High Professional Customization/ Multi Function SMT Line Automatic Factory in China

Best Selling Heller Reflow Soldering Oven Machine For SMT Machine Line

High Speed 6 Heads Multi-functional SMT Pick and Place Machine LED Automatic

Contacts:Eva Liu +8613450659407 +86 13416743702

Tel:+86-512-62751429

Skype:evaliuhuan

Email: caojun@hk-yush.com sales@yushunli.com evaliu@hk-yush.com

Address: Building H, GuoRui Pioneering Park,

No. 1068 Jinyang East Road, Lujia Town, Kunshan,

Suzhou.

Postcode:215331

Dongguan Factory Address: 5th Floor, No.10, Shanquan Road,

Yongtou Village, Chang’an Town, Dongguan City, Guangdong

province,

China.

Postcode:523843