Basic specifications:

1. X, Y cutting speed: 0 ~100mm/s

2. Machine Repeat Accuracy: ± 0.01mm

3. X, Y1,Y2 ,Z Control Methods: Industrial IPC and PC

4. X, Y1,Y2 ,Z Drive Mode: AC Fiber Optic Servo Motor

5. Machine Operation and Data Storage: PC System

6. Cutting accuracy: ± 0.05mm

7. Spindle speed: Max 100000pm

8. Host voltage: 220V 1ψ 50 / 60HZ

9. Air pressure supply: above 4.5kg/cm2

10. Power Consumption: 3KVA

11. Dust Collection: Upper Dust Collection 2HP

12. Dust collector voltage: 380V 3ψ

13. Upper dust collector size: :L650*W400*H1350mm

|

Workbench |

Model |

Specifications |

Work Size |

Machine Dimension W.D.H |

Net Weight |

|

Double Tables |

MT-3000-IN-AS |

Standard Type |

300*300mm |

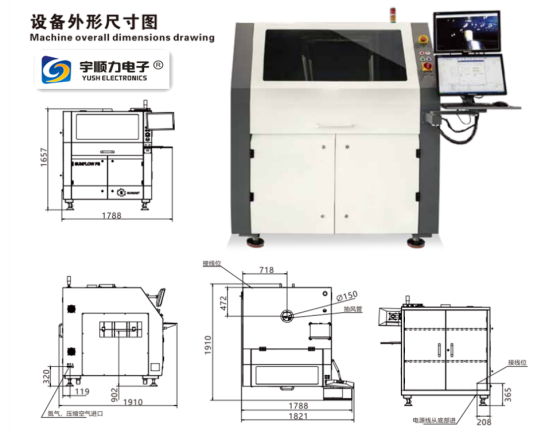

1680*1298*1700mm |

1100KG |

|

Double Tables |

MT-3000-IN-AW |

Widened |

500*450mm |

1902*1373*1700mm |

1400KG |

Choose high-vacuum dust-removing motor, the noise is less than 75 decibels. Use the follow-up technology to control the vacuum brush, follow the cutting tool to move at the same speed, maintain the best suction position at the right time, and then cooperate with the auxiliary vacuum to efficiently rotate the cutter due to the high speed The dust is collected on the surface of the PCB and the work surface by cutting.

Basic specifications:

1. X, Y cutting speed: 0 ~100mm/s

2. Machine Repeat Accuracy: ± 0.01mm

3. X, Y1,Y2 ,Z Control Methods: Industrial IPC and PC

4. X, Y1,Y2 ,Z Drive Mode: AC Fiber Optic Servo Motor

5. Machine Operation and Data Storage: PC System

6. Cutting accuracy: ± 0.05mm

7. Spindle speed: Max 100000pm

8. Host voltage: 220V 1ψ 50 / 60HZ

9. Air pressure supply: above 4.5kg/cm2

10. Power Consumption: 3KVA

11. Dust Collection: Upper Dust Collection 2HP

12. Dust collector voltage: 380V 3ψ

13. Upper dust collector size: :L650*W400*H1350mm

|

Workbench |

Model |

Specifications |

Work Size |

Machine Dimension W.D.H |

Net Weight |

|

Double Tables |

MT-3000-IN-AS |

Standard Type |

300*300mm |

1680*1298*1700mm |

1100KG |

|

Double Tables |

MT-3000-IN-AW |

Widened |

500*450mm |

1902*1373*1700mm |

1400KG |

Choose high-vacuum dust-removing motor, the noise is less than 75 decibels. Use the follow-up technology to control the vacuum brush, follow the cutting tool to move at the same speed, maintain the best suction position at the right time, and then cooperate with the auxiliary vacuum to efficiently rotate the cutter due to the high speed The dust is collected on the surface of the PCB and the work surface by cutting.

SMT placement machine placement machine parts placement machine

Dual arm magnetic linear LED highspeed pick and place machine

SMT Machine/ High Professional Customization/ Multi Function SMT Line Automatic Factory in China

Best Selling Heller Reflow Soldering Oven Machine For SMT Machine Line

High Speed 6 Heads Multi-functional SMT Pick and Place Machine LED Automatic

Contacts:Eva Liu +8613450659407 +86 13416743702

Tel:+86-512-62751429

Skype:evaliuhuan

Email: caojun@hk-yush.com sales@yushunli.com evaliu@hk-yush.com

Address: Building H, GuoRui Pioneering Park,

No. 1068 Jinyang East Road, Lujia Town, Kunshan,

Suzhou.

Postcode:215331

Dongguan Factory Address: 5th Floor, No.10, Shanquan Road,

Yongtou Village, Chang’an Town, Dongguan City, Guangdong

province,

China.

Postcode:523843