Ultraviolet laser cutting machine MicroScan5000DP:

●Working Table: The dual-platform working mode, one-in-one, always keeps the equipment connected uninterrupted and greatly improves production efficiency. It is a device specially designed for FPC and PCB processing

●Efficient and fast FPC/PCB external cutting, drilling and film opening window, fingerprint identification chip cutting, TF memory card sub-board, mobile phone camera module cutting and other applications

●The block, layer, designated block or selected area is cut and directly formed, and the cutting edge is round and smooth, smooth and burr-free, and there is no overflow. The product can be arranged in multiple rows for automatic positioning and cutting, especially suitable for cutting of fine, difficult and complicated patterns

●High-performance laser: It adopts the international first-line brand solid-state UV laser, which has the advantages of good beam quality, small focusing spot, uniform power distribution, small thermal effect, small slit width and high cutting quality

● Fast and high precision: The combination of high-precision, low-drift galvanometer and fast iron-free linear motor system platform ensures fast cutting while maintaining high precision on the order of micrometers

● Fully automatic positioning: High-precision CCD automatic positioning and focusing, making positioning fast and accurate, high precision, no manual intervention, simple operation, realizing the same type of one-button mode, greatly improving production efficiency

●Exhaust gas treatment system: The suction system can completely eliminate the cutting exhaust gas, avoiding the harm to the operator and the pollution to the environment

●High degree of automation: automatic correction of galvanometer, automatic focusing, automatic realization of the whole process, automatic adjustment of the focus to the height of the table by laser displacement sensor, realizing rapid alignment, saving time and worry

●Easy to learn software: Self-developed Windows-based control software, easy-to-operate Chinese interface, friendly and beautiful, powerful and diverse, easy to operate

MicroScan5000DP specification sheet:

1. Equipment Model MicroScan 5000DP

2. Accessories Configuration Laser Brand Lightwave (Optowave) / USA

3. Laser power 15W

4. Laser properties All solid state UV laser

5. Laser wavelength 355nm

6. Galvanometer SCANLAB/CTI Germany

7. Field Mirror SILL/JENOPTIK Germany

8. Guide rail HIWIN/Taiwan

9. Mirrors American Lightwave (Optowave)

10. Grating ruler Renishaw/USA

11.CCD MVC/Italy

driver:

1. Yaskawa / Japan

.2. Mirror Lightwave (Optowave) / USA

3. Linear motor igus/Shanghai Yichu

4.355 Beam Expander Optical Wave (Optowave) / USA

5. Linear motor HIWIN/Taiwan

6.355 Beam Expander US Light Wave (Optowave)

7. Dust processor HOYAN / Fire 焱 own research and development

8. Equipment body Marble / Qingdao

9. Motion Control Card Qianliyun / Shenzhen, China

10. Cutting software Hoyan-ScanCut/Fireworks own research and development

11. Spot diameter 20 ± 5um

12. The maximum scanning range of the galvanometer 50mm*50mm

Performance configuration:

1. The thickness of the cutting substrate is less than 1.2mm (different cutting quality depending on the material)

2. Repeat positioning accuracy ±2 μm

3. Positioning accuracy ±2 μm

4. Machine machining accuracy ±20 μm

5. Maximum format 350*450mm*350*450mm (2 Tables)

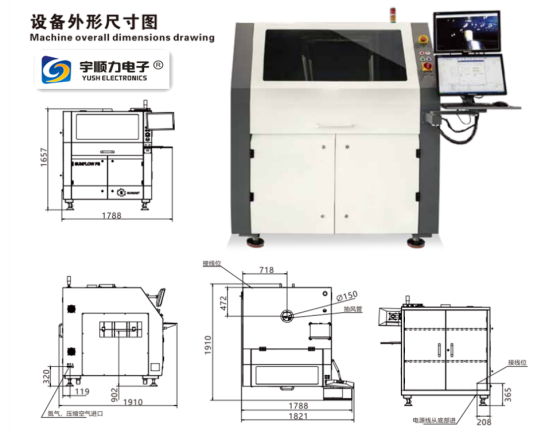

6. Equipment size 1350mm (L) × 1150mm (W) × 1550mm (H)

7. Support document format Gerber/DXF

8. Equipment weight 2000KG

9. Working mode Double Table switching

Environmental requirements:

Working power supply AC220V / 3.5KW

Grid demand (two-phase) single-phase AC AC220V

Temperature 20±2 °C

Humidity 50-60% without condensation

Air pressure demand 0.5~0.6Mpa (not required for single machine)

Vibration ≤5um

Environmental needs:

20±2 °C /50-60% no condensation

Special function Laser QR code (metal / white oil surface

Cutting material type Cover film, pure rubber, blue film, FR4, PP, PI, FPC, PC

Ultraviolet laser cutting machine MicroScan5000DP:

●Working Table: The dual-platform working mode, one-in-one, always keeps the equipment connected uninterrupted and greatly improves production efficiency. It is a device specially designed for FPC and PCB processing

●Efficient and fast FPC/PCB external cutting, drilling and film opening window, fingerprint identification chip cutting, TF memory card sub-board, mobile phone camera module cutting and other applications

●The block, layer, designated block or selected area is cut and directly formed, and the cutting edge is round and smooth, smooth and burr-free, and there is no overflow. The product can be arranged in multiple rows for automatic positioning and cutting, especially suitable for cutting of fine, difficult and complicated patterns

●High-performance laser: It adopts the international first-line brand solid-state UV laser, which has the advantages of good beam quality, small focusing spot, uniform power distribution, small thermal effect, small slit width and high cutting quality

● Fast and high precision: The combination of high-precision, low-drift galvanometer and fast iron-free linear motor system platform ensures fast cutting while maintaining high precision on the order of micrometers

● Fully automatic positioning: High-precision CCD automatic positioning and focusing, making positioning fast and accurate, high precision, no manual intervention, simple operation, realizing the same type of one-button mode, greatly improving production efficiency

●Exhaust gas treatment system: The suction system can completely eliminate the cutting exhaust gas, avoiding the harm to the operator and the pollution to the environment

●High degree of automation: automatic correction of galvanometer, automatic focusing, automatic realization of the whole process, automatic adjustment of the focus to the height of the table by laser displacement sensor, realizing rapid alignment, saving time and worry

●Easy to learn software: Self-developed Windows-based control software, easy-to-operate Chinese interface, friendly and beautiful, powerful and diverse, easy to operate

MicroScan5000DP specification sheet:

1. Equipment Model MicroScan 5000DP

2. Accessories Configuration Laser Brand Lightwave (Optowave) / USA

3. Laser power 15W

4. Laser properties All solid state UV laser

5. Laser wavelength 355nm

6. Galvanometer SCANLAB/CTI Germany

7. Field Mirror SILL/JENOPTIK Germany

8. Guide rail HIWIN/Taiwan

9. Mirrors American Lightwave (Optowave)

10. Grating ruler Renishaw/USA

11.CCD MVC/Italy

driver:

1. Yaskawa / Japan

.2. Mirror Lightwave (Optowave) / USA

3. Linear motor igus/Shanghai Yichu

4.355 Beam Expander Optical Wave (Optowave) / USA

5. Linear motor HIWIN/Taiwan

6.355 Beam Expander US Light Wave (Optowave)

7. Dust processor HOYAN / Fire 焱 own research and development

8. Equipment body Marble / Qingdao

9. Motion Control Card Qianliyun / Shenzhen, China

10. Cutting software Hoyan-ScanCut/Fireworks own research and development

11. Spot diameter 20 ± 5um

12. The maximum scanning range of the galvanometer 50mm*50mm

Performance configuration:

1. The thickness of the cutting substrate is less than 1.2mm (different cutting quality depending on the material)

2. Repeat positioning accuracy ±2 μm

3. Positioning accuracy ±2 μm

4. Machine machining accuracy ±20 μm

5. Maximum format 350*450mm*350*450mm (2 Tables)

6. Equipment size 1350mm (L) × 1150mm (W) × 1550mm (H)

7. Support document format Gerber/DXF

8. Equipment weight 2000KG

9. Working mode Double Table switching

Environmental requirements:

Working power supply AC220V / 3.5KW

Grid demand (two-phase) single-phase AC AC220V

Temperature 20±2 °C

Humidity 50-60% without condensation

Air pressure demand 0.5~0.6Mpa (not required for single machine)

Vibration ≤5um

Environmental needs:

20±2 °C /50-60% no condensation

Special function Laser QR code (metal / white oil surface

Cutting material type Cover film, pure rubber, blue film, FR4, PP, PI, FPC, PC

SMT placement machine placement machine parts placement machine

Dual arm magnetic linear LED highspeed pick and place machine

SMT Machine/ High Professional Customization/ Multi Function SMT Line Automatic Factory in China

Best Selling Heller Reflow Soldering Oven Machine For SMT Machine Line

High Speed 6 Heads Multi-functional SMT Pick and Place Machine LED Automatic

Contacts:Eva Liu +8613450659407 +86 13416743702

Tel:+86-512-62751429

Skype:evaliuhuan

Email: caojun@hk-yush.com sales@yushunli.com evaliu@hk-yush.com

Address: Building H, GuoRui Pioneering Park,

No. 1068 Jinyang East Road, Lujia Town, Kunshan,

Suzhou.

Postcode:215331

Dongguan Factory Address: 5th Floor, No.10, Shanquan Road,

Yongtou Village, Chang’an Town, Dongguan City, Guangdong

province,

China.

Postcode:523843