automatic screen stencil Clean Machine -YS-750

Features:

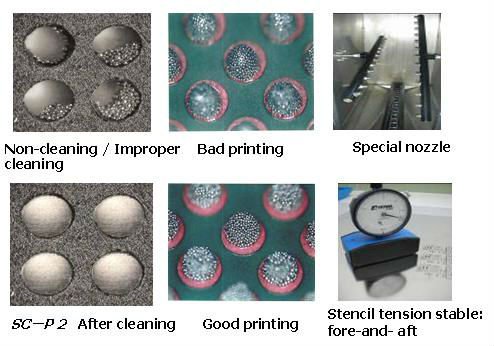

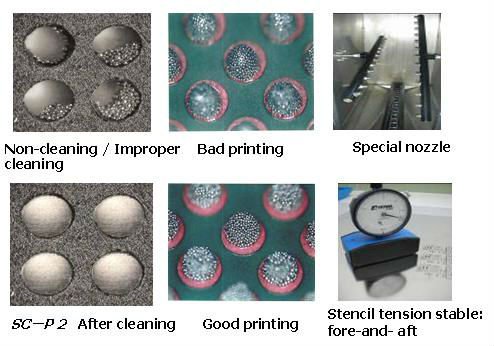

1. Special nozzle design ensures high cleaning performance. Stencil tension is not affected during the cleaning process.

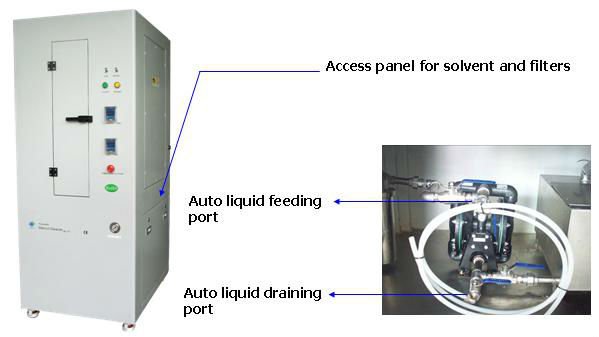

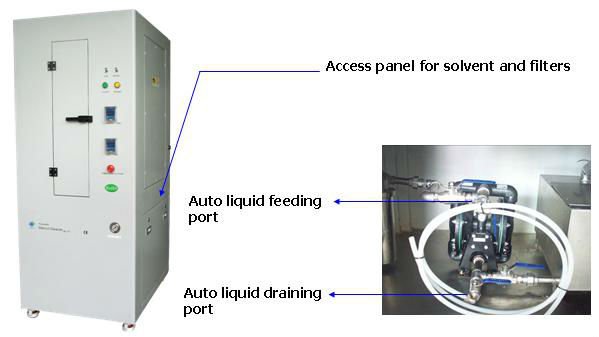

2. Auto liquid feeding and draining system.

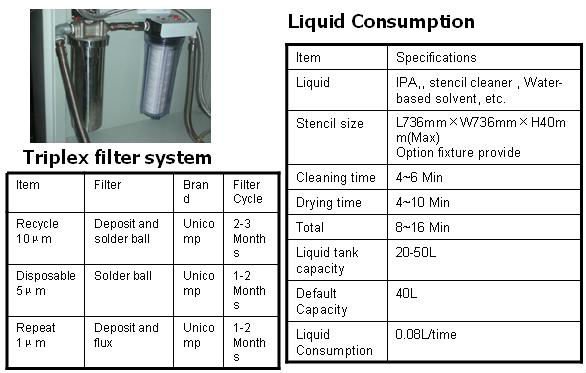

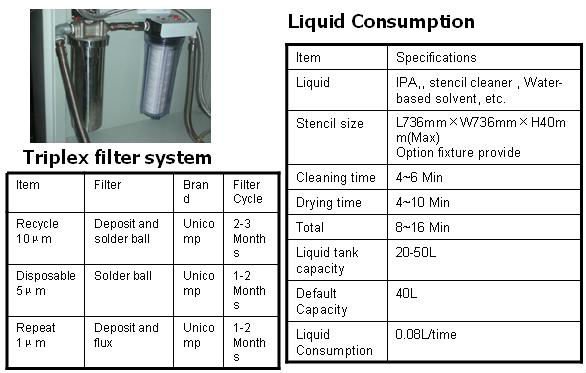

3. Triplex filter system with precise exhaust design and control. Liquid can be recycled which results in lower solvent consumption.

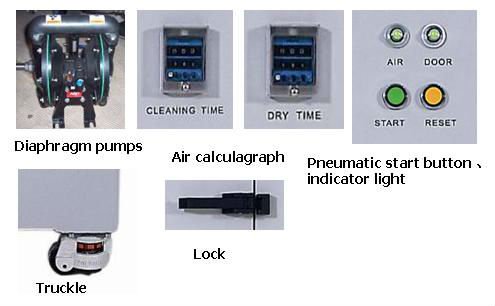

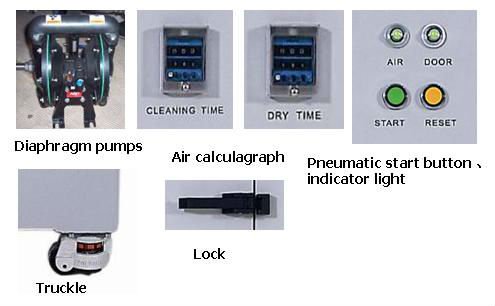

4. Internationally recognized critical components are used to ensure long term quality and reliability.Modular design to ensure easy maintenance.

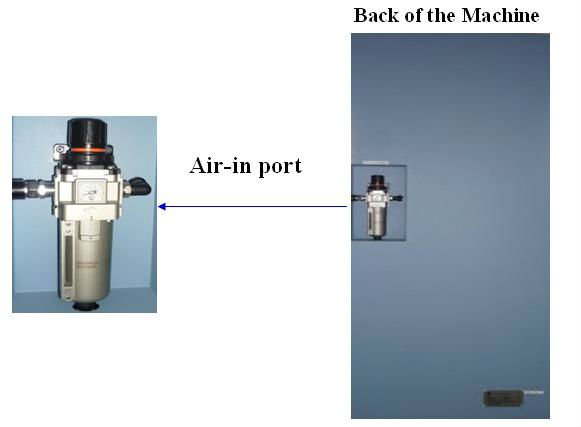

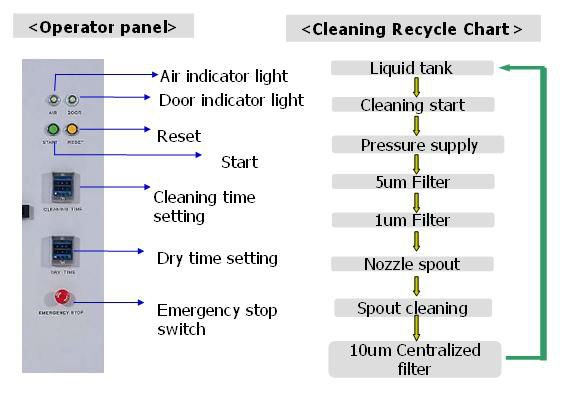

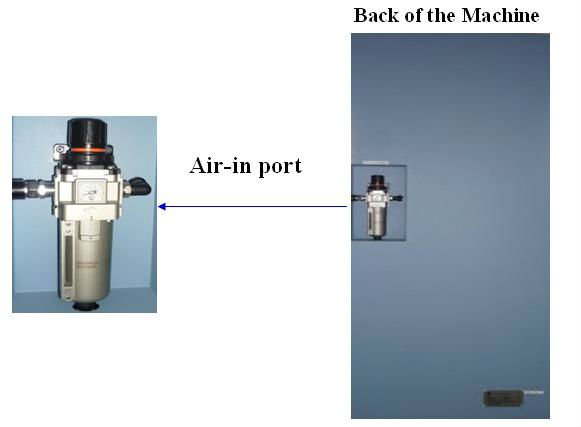

5. Completely pneumatic operation without any fire risk.

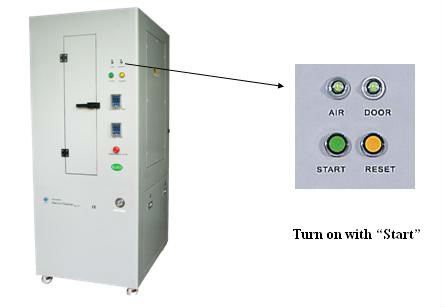

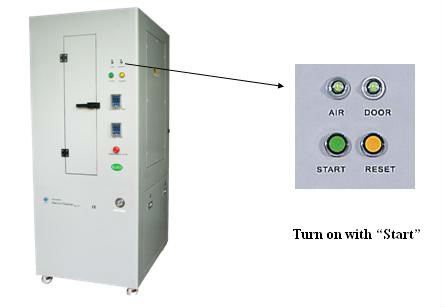

6. Equipment is ergonomically in designed. Cleaning and drying process can be easily control with one-button operation.

7. YS-750 is designed for cleaning of solder paste, glue and silicone adhesive.

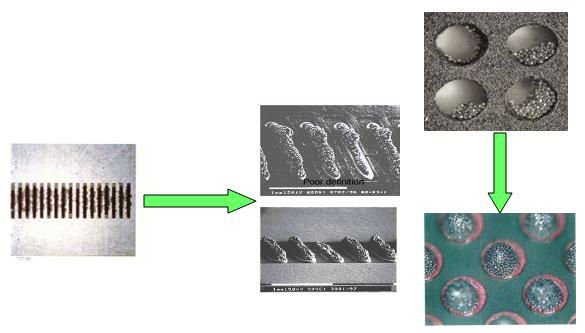

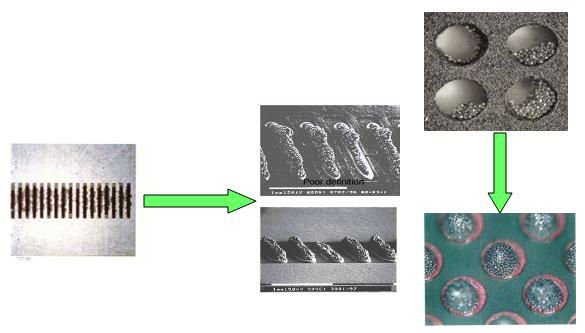

1. Solder paste and glue will adhere to the stencil hole during printing process.

2. Manual cleaning is not effective in removing the solder paste deposit. Solidified and hardened deposits can cause the stencil mesh to deform.

3. The printing quality will be adversely affected if the stencil is used without proper cleaning

Equipment is ergonomically designed. Cleaning and drying process can be easily control with one-button operation

Special nozzle design ensures high cleaning performance.

Stencil tension is not affected during the cleaning process.

Auto liquid feeding and draining system.

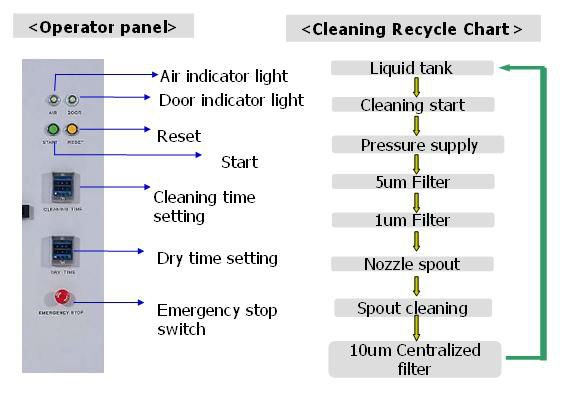

Triplex filter system with precise exhaust design and control. Liquid can be recycled which results in lower solvent consumption.

Modular design to ensure easy maintenance

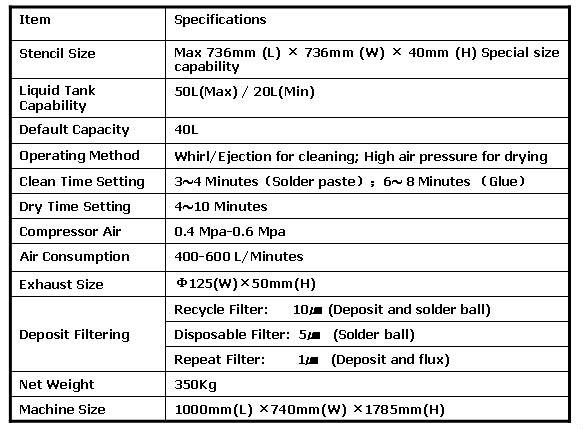

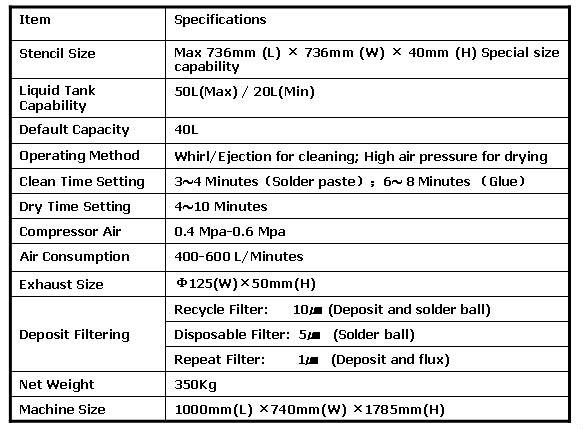

Specifications: Pneumatic stencil cleaner

automatic screen stencil Clean Machine -YS-750

Features:

1. Special nozzle design ensures high cleaning performance. Stencil tension is not affected during the cleaning process.

2. Auto liquid feeding and draining system.

3. Triplex filter system with precise exhaust design and control. Liquid can be recycled which results in lower solvent consumption.

4. Internationally recognized critical components are used to ensure long term quality and reliability.Modular design to ensure easy maintenance.

5. Completely pneumatic operation without any fire risk.

6. Equipment is ergonomically in designed. Cleaning and drying process can be easily control with one-button operation.

7. YS-750 is designed for cleaning of solder paste, glue and silicone adhesive.

1. Solder paste and glue will adhere to the stencil hole during printing process.

2. Manual cleaning is not effective in removing the solder paste deposit. Solidified and hardened deposits can cause the stencil mesh to deform.

3. The printing quality will be adversely affected if the stencil is used without proper cleaning

Equipment is ergonomically designed. Cleaning and drying process can be easily control with one-button operation

Special nozzle design ensures high cleaning performance.

Stencil tension is not affected during the cleaning process.

Auto liquid feeding and draining system.

Triplex filter system with precise exhaust design and control. Liquid can be recycled which results in lower solvent consumption.

Modular design to ensure easy maintenance

Specifications: Pneumatic stencil cleaner

SMT placement machine placement machine parts placement machine

Dual arm magnetic linear LED highspeed pick and place machine

SMT Machine/ High Professional Customization/ Multi Function SMT Line Automatic Factory in China

Best Selling Heller Reflow Soldering Oven Machine For SMT Machine Line

High Speed 6 Heads Multi-functional SMT Pick and Place Machine LED Automatic

Contacts:Eva Liu +8613450659407 +86 13416743702

Tel:+86-512-62751429

Skype:evaliuhuan

Email: caojun@hk-yush.com sales@yushunli.com evaliu@hk-yush.com

Address: Building H, GuoRui Pioneering Park,

No. 1068 Jinyang East Road, Lujia Town, Kunshan,

Suzhou.

Postcode:215331

Dongguan Factory Address: 5th Floor, No.10, Shanquan Road,

Yongtou Village, Chang’an Town, Dongguan City, Guangdong

province,

China.

Postcode:523843