10.Integral stainless steel fuselage, strong and durable, resistant to acid, alkali cleaning fluid, etc

13. Lower running cost, every time only 12 l liquid cleaning, clean end use compressed air recycling pipeline and pump more than residual liquid, liquid consumption can reduce 50%

Specification

| Apply screen size |

Max 740mm(L) ×740mm(W) × 40mm(H)

|

| Cleaning fluid capacity |

50L*2PCS(max)

|

| Best liquid usage |

40L*2PCS

|

| Clean and risn method |

Left-right moving high pressure liquid spray cleaning

|

| Drying method |

High pressure hot air(Optional super models)

|

| Clean time |

2-5 Min

|

| Cleaning fluid separation time |

40S

|

| Rinse time |

2-5 Min

|

| Rinse times |

1-99times (adjustable)

|

| Drying time |

2-5Min

|

| Cleaning liquid recycling |

1μm (Micro filter: rosin, solder paste, flux and pollutants)

|

| Rinse liquid emission filter |

5μm (Micro filter: rosin, solder paste, flux and pollutants)

|

| Liquid heating temperature |

room temp~60°C

|

| noise |

Less than 50 decibels

|

| Range of resistivity tester |

0~18MΩ

|

| DI water supply |

30~60L/min

|

| DI water pressure |

≤0.4Mpa

|

| DI water Gateway connecting pipe |

1 Inch |

| Air supply |

0.45Mpa ~0.7Mpa

|

| Power supply |

AC380V 50HZ 65A

|

| Total power |

33KW

|

| Net weight |

500Kg

|

| Air out size |

Φ124(W)×30mm(H)

|

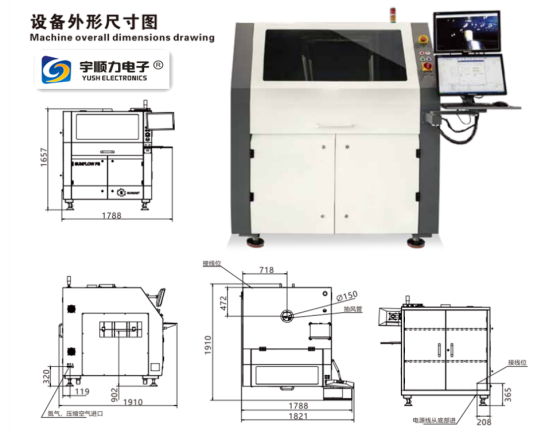

| Dimension |

1600mm(L) ×1160mm(W) ×1850mm(H)

|

10.Integral stainless steel fuselage, strong and durable, resistant to acid, alkali cleaning fluid, etc

13. Lower running cost, every time only 12 l liquid cleaning, clean end use compressed air recycling pipeline and pump more than residual liquid, liquid consumption can reduce 50%

Specification

| Apply screen size |

Max 740mm(L) ×740mm(W) × 40mm(H)

|

| Cleaning fluid capacity |

50L*2PCS(max)

|

| Best liquid usage |

40L*2PCS

|

| Clean and risn method |

Left-right moving high pressure liquid spray cleaning

|

| Drying method |

High pressure hot air(Optional super models)

|

| Clean time |

2-5 Min

|

| Cleaning fluid separation time |

40S

|

| Rinse time |

2-5 Min

|

| Rinse times |

1-99times (adjustable)

|

| Drying time |

2-5Min

|

| Cleaning liquid recycling |

1μm (Micro filter: rosin, solder paste, flux and pollutants)

|

| Rinse liquid emission filter |

5μm (Micro filter: rosin, solder paste, flux and pollutants)

|

| Liquid heating temperature |

room temp~60°C

|

| noise |

Less than 50 decibels

|

| Range of resistivity tester |

0~18MΩ

|

| DI water supply |

30~60L/min

|

| DI water pressure |

≤0.4Mpa

|

| DI water Gateway connecting pipe |

1 Inch |

| Air supply |

0.45Mpa ~0.7Mpa

|

| Power supply |

AC380V 50HZ 65A

|

| Total power |

33KW

|

| Net weight |

500Kg

|

| Air out size |

Φ124(W)×30mm(H)

|

| Dimension |

1600mm(L) ×1160mm(W) ×1850mm(H)

|

SMT placement machine placement machine parts placement machine

Dual arm magnetic linear LED highspeed pick and place machine

SMT Machine/ High Professional Customization/ Multi Function SMT Line Automatic Factory in China

Best Selling Heller Reflow Soldering Oven Machine For SMT Machine Line

High Speed 6 Heads Multi-functional SMT Pick and Place Machine LED Automatic

Contacts:Eva Liu +8613450659407 +86 13416743702

Tel:+86-512-62751429

Skype:evaliuhuan

Email: caojun@hk-yush.com sales@yushunli.com evaliu@hk-yush.com

Address: Building H, GuoRui Pioneering Park,

No. 1068 Jinyang East Road, Lujia Town, Kunshan,

Suzhou.

Postcode:215331

Dongguan Factory Address: 5th Floor, No.10, Shanquan Road,

Yongtou Village, Chang’an Town, Dongguan City, Guangdong

province,

China.

Postcode:523843