product description

1. AOI principle: use modern optical principles and digital camera technology to shoot the detected object in real time, analyze and process the captured image through computer and special software, and automatically generate detection results.

2. AOI function: AOI effective detection rate: more than 99% (manual detection rate: about 70%);

Reduce labor: 2-4 people/production line, high detection efficiency;

Through the SPC function, the process defects can be accurately and accurately counted, which can be effectively controlled;

The stability is much higher than that of labor, and the comprehensive cost can be significantly reduced after long-term use;

It can enhance the company's comprehensive strength and effectively improve the company's overall competitiveness.

3. AOI advantages:

1) Checkable items:

After wave soldering of DIP plug-in: more tin, less tin, tin holes, short circuit, pins not coming out, etc.

SMT: missing parts, dislocation, wrong parts, reverse polarity, damage, pollution, less tin, more tin, short circuit, virtual welding, etc.

2) Powerful software functions

◆Color extraction, statistical analysis ◆Character recognition (OCR) ◆Color distance analysis

◆IC bridging ◆Black and white specific gravity analysis ◆Brightness analysis

◆Graphic similarity analysis ◆CAD data import ◆SPC statistical function

◆Operation level management ◆Barcode scanning ◆Offline programming

◆CAD data function ◆Automatic identification and detection of bottom surface ◆Multiple panel detection

◆Multi-machine interconnection ◆Self-built component standard library ◆It can generate and export daily, weekly and monthly reports

◆Can be connected to multiple maintenance stations

3) Precise mechanical structure design

◆High rigidity base, reasonable center of gravity, small vibration during operation, beautiful appearance

◆Precise screw guides and wire guides

◆Precision automatic fixture, convenient and quick to load and unload PCB

◆Exquisite assembly skills ensure the stable use and long life of the whole machine.

4) Stable electrical control

◆Servo drive system, stable and mature

◆LS mature and stable motion control

◆EPIX advanced image capture and processing technology

◆Omron stable various electrical components, long service life

◆LAAP high-flexible drag chain cable, the service life can reach 5-8 million times

◆Stable circuit, easy maintenance and safety.

5) Scientific light source design

◆Philips LED

◆The overall processing technology ensures the accuracy of the illumination angle of the light source

◆Strict brightness detection

◆Strict aging test to ensure a service life of 50,000 hours

◆Scientific use of the principle of three-color light can make the components show different colors of the body and solder at different angles to achieve accurate detection purposes

| Main components configuration list | ||||

| No. | Name | Brand | Unit | Quantity |

| 1 | guide | Bank of Taiwan | Strip | 4 |

| 2 | screw | Bank of Taiwan | Strip | 2 |

| 3 | Screw seat | Bank of Taiwan | Set | 2 |

| 4 | Motors and Drives | 200W Servo Motor | Set | 2 |

| 5 | camera | 5 million pixel CCD color camera | Set | 1 |

| 6 | lens | Qing Cheng | Indivual | 1 |

| 7 | sports card | Raise | Set | 1 |

| 8 | color light source | Three-color coaxial light source RGB | Set | 1 |

| 9 | slot switch | Omron | Only | 2 |

| 10 | switching power supply | Mean Well Taiwan | Only | 1 |

| 11 | leakage protector | Schneider, Chint | Only | 1 |

| 12 | open | Schneider, Chint | Only | 3 |

| 13 | Intermediate relay | Omron (not used) | Set | 2 |

| IPC configuration | computer | Industrial computer chassis | Tower | 1 |

| monitor | Dell 22" | Tower | 1 | |

| CPU | Intel i5-4460 Quad Core | Set | 1 | |

| motherboard | P5P41T | |||

| Memory | Kingston 8G | |||

| hard disk | 1T | |||

| CD-ROM | Pioneer DVD (not used) | |||

| Chassis power | 450W | |||

| Applicable PCB | Applicable process | After SMT solder paste printing and reflow soldering, the circuit board inspection after reflow soldering can detect both sides of the PCB and detect multiple PCBs at the same time |

| After wave soldering of the DIP plug-in: more tin, less tin, tin holes, short circuit, the pins are not out. | ||

| Substrate size | 25×25mm-550×460mm (large size can be customized) | |

| Substrate thickness | 0.3-5.0mm | |

| Clear height above and below the substrate | Top: ≤35mm; Bottom: ≤50mm (can be customized according to customer requirements) | |

| After reflow | Missing parts, multiple parts, solder balls, offset, side standing, tombstone, reverse sticking, extremely reverse, wrong parts, bad parts, bridge connection, virtual soldering, no solder, less solder, more solder, component floating, IC Leads are floating, IC leads are bent | |

| DIP plug-in after wave soldering | More tin, less tin, tin hole, short circuit, pin not coming out, etc. | |

| Visual system | camera system | Full-color high-speed digital CCD camera |

| Lighting system | Three-channel white LED light source or GRB light source | |

| Resolution | 10um, 15um, 18um, 20um, 25um are optional. | |

| Detection method | Color extraction, set color scale parameters | |

| Computer system | X/Y drive system | Servo motor + precision ground ball screw |

| splint | Automatic Fixture | |

| positioning accuracy | <8um | |

| Moving speed | 800mm/s(MAX) | |

| Orbit adjustment | manual | |

| Software system | operating system | Windows10.64 Professional Edition |

| interface language | Chinese and English optional interface | |

| Test result output | Substrate ID, Substrate Name, Component Name, Defect Name, Defect Picture | |

| Power Specifications | AC220±10%, 50/60HZ, 1KW | |

| Ambient temperature | -10-40℃ | |

| Environment humidity | 20-90%RH (no frosting) | |

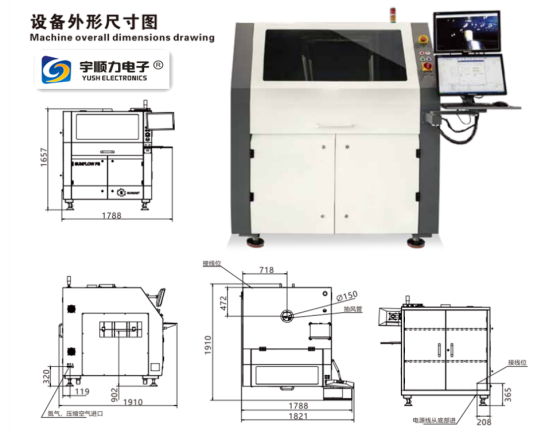

| Overall size | 980*910*1300 | |

product description

1. AOI principle: use modern optical principles and digital camera technology to shoot the detected object in real time, analyze and process the captured image through computer and special software, and automatically generate detection results.

2. AOI function: AOI effective detection rate: more than 99% (manual detection rate: about 70%);

Reduce labor: 2-4 people/production line, high detection efficiency;

Through the SPC function, the process defects can be accurately and accurately counted, which can be effectively controlled;

The stability is much higher than that of labor, and the comprehensive cost can be significantly reduced after long-term use;

It can enhance the company's comprehensive strength and effectively improve the company's overall competitiveness.

3. AOI advantages:

1) Checkable items:

After wave soldering of DIP plug-in: more tin, less tin, tin holes, short circuit, pins not coming out, etc.

SMT: missing parts, dislocation, wrong parts, reverse polarity, damage, pollution, less tin, more tin, short circuit, virtual welding, etc.

2) Powerful software functions

◆Color extraction, statistical analysis ◆Character recognition (OCR) ◆Color distance analysis

◆IC bridging ◆Black and white specific gravity analysis ◆Brightness analysis

◆Graphic similarity analysis ◆CAD data import ◆SPC statistical function

◆Operation level management ◆Barcode scanning ◆Offline programming

◆CAD data function ◆Automatic identification and detection of bottom surface ◆Multiple panel detection

◆Multi-machine interconnection ◆Self-built component standard library ◆It can generate and export daily, weekly and monthly reports

◆Can be connected to multiple maintenance stations

3) Precise mechanical structure design

◆High rigidity base, reasonable center of gravity, small vibration during operation, beautiful appearance

◆Precise screw guides and wire guides

◆Precision automatic fixture, convenient and quick to load and unload PCB

◆Exquisite assembly skills ensure the stable use and long life of the whole machine.

4) Stable electrical control

◆Servo drive system, stable and mature

◆LS mature and stable motion control

◆EPIX advanced image capture and processing technology

◆Omron stable various electrical components, long service life

◆LAAP high-flexible drag chain cable, the service life can reach 5-8 million times

◆Stable circuit, easy maintenance and safety.

5) Scientific light source design

◆Philips LED

◆The overall processing technology ensures the accuracy of the illumination angle of the light source

◆Strict brightness detection

◆Strict aging test to ensure a service life of 50,000 hours

◆Scientific use of the principle of three-color light can make the components show different colors of the body and solder at different angles to achieve accurate detection purposes

| Main components configuration list | ||||

| No. | Name | Brand | Unit | Quantity |

| 1 | guide | Bank of Taiwan | Strip | 4 |

| 2 | screw | Bank of Taiwan | Strip | 2 |

| 3 | Screw seat | Bank of Taiwan | Set | 2 |

| 4 | Motors and Drives | 200W Servo Motor | Set | 2 |

| 5 | camera | 5 million pixel CCD color camera | Set | 1 |

| 6 | lens | Qing Cheng | Indivual | 1 |

| 7 | sports card | Raise | Set | 1 |

| 8 | color light source | Three-color coaxial light source RGB | Set | 1 |

| 9 | slot switch | Omron | Only | 2 |

| 10 | switching power supply | Mean Well Taiwan | Only | 1 |

| 11 | leakage protector | Schneider, Chint | Only | 1 |

| 12 | open | Schneider, Chint | Only | 3 |

| 13 | Intermediate relay | Omron (not used) | Set | 2 |

| IPC configuration | computer | Industrial computer chassis | Tower | 1 |

| monitor | Dell 22" | Tower | 1 | |

| CPU | Intel i5-4460 Quad Core | Set | 1 | |

| motherboard | P5P41T | |||

| Memory | Kingston 8G | |||

| hard disk | 1T | |||

| CD-ROM | Pioneer DVD (not used) | |||

| Chassis power | 450W | |||

| Applicable PCB | Applicable process | After SMT solder paste printing and reflow soldering, the circuit board inspection after reflow soldering can detect both sides of the PCB and detect multiple PCBs at the same time |

| After wave soldering of the DIP plug-in: more tin, less tin, tin holes, short circuit, the pins are not out. | ||

| Substrate size | 25×25mm-550×460mm (large size can be customized) | |

| Substrate thickness | 0.3-5.0mm | |

| Clear height above and below the substrate | Top: ≤35mm; Bottom: ≤50mm (can be customized according to customer requirements) | |

| After reflow | Missing parts, multiple parts, solder balls, offset, side standing, tombstone, reverse sticking, extremely reverse, wrong parts, bad parts, bridge connection, virtual soldering, no solder, less solder, more solder, component floating, IC Leads are floating, IC leads are bent | |

| DIP plug-in after wave soldering | More tin, less tin, tin hole, short circuit, pin not coming out, etc. | |

| Visual system | camera system | Full-color high-speed digital CCD camera |

| Lighting system | Three-channel white LED light source or GRB light source | |

| Resolution | 10um, 15um, 18um, 20um, 25um are optional. | |

| Detection method | Color extraction, set color scale parameters | |

| Computer system | X/Y drive system | Servo motor + precision ground ball screw |

| splint | Automatic Fixture | |

| positioning accuracy | <8um | |

| Moving speed | 800mm/s(MAX) | |

| Orbit adjustment | manual | |

| Software system | operating system | Windows10.64 Professional Edition |

| interface language | Chinese and English optional interface | |

| Test result output | Substrate ID, Substrate Name, Component Name, Defect Name, Defect Picture | |

| Power Specifications | AC220±10%, 50/60HZ, 1KW | |

| Ambient temperature | -10-40℃ | |

| Environment humidity | 20-90%RH (no frosting) | |

| Overall size | 980*910*1300 | |

SMT placement machine placement machine parts placement machine

Dual arm magnetic linear LED highspeed pick and place machine

SMT Machine/ High Professional Customization/ Multi Function SMT Line Automatic Factory in China

Best Selling Heller Reflow Soldering Oven Machine For SMT Machine Line

High Speed 6 Heads Multi-functional SMT Pick and Place Machine LED Automatic

Contacts:Eva Liu +8613450659407 +86 13416743702

Tel:+86-512-62751429

Skype:evaliuhuan

Email: caojun@hk-yush.com sales@yushunli.com evaliu@hk-yush.com

Address: Building H, GuoRui Pioneering Park,

No. 1068 Jinyang East Road, Lujia Town, Kunshan,

Suzhou.

Postcode:215331

Dongguan Factory Address: 5th Floor, No.10, Shanquan Road,

Yongtou Village, Chang’an Town, Dongguan City, Guangdong

province,

China.

Postcode:523843