Precision laser cutting dust removal

Applicable working conditions

Mainly used for the collection and treatment of floating and suspended dust with a large amount of dust, and small central dust collection systems for multi-station operations; suitable for grinding, cutting, stirring, sandblasting, ceramics, paper, steel, food, plastic, Wood processing and other industries;

Product Features

1. Large air volume and low noise, industrial fans can work continuously for 24 hours;

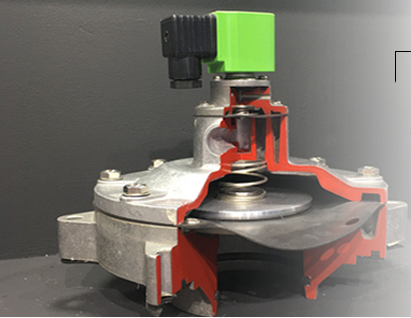

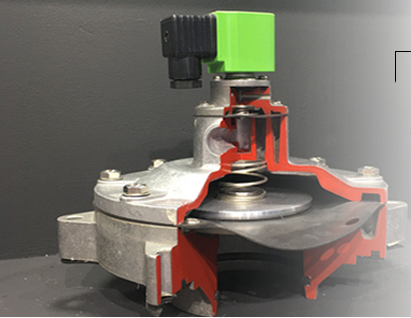

2.4 automatic pulse cleaning systems for PTFE-coated filter cartridges;

3. It can be matched with small laser cutting machines for dust removal; engraving machines, grinders/belt machines, rubber cutting machines, grinders, milling machines and other machining equipment are matched with dust removal. It is mostly used for the collection and treatment of floating and suspended dust.

4.2.0 sheet metal, independent electrical box, built-in air duct

5. Separate dust collecting bucket with see-through window, you only need to lift and pull the dust collecting bucket to pull out the dust collecting bucket. There is a universal wheel under the dust collecting bucket, which is very convenient for dumping and inhaling materials.

6.68DB noise reduction technology can be placed indoors and outdoors to keep front-line employees away from noise hazards.

| Specification | Unit | YSL-370 | YSL-550 |

| Power | Kw | 3.7 | 5.5 |

| Voltage | V | 380V 50Hz/60Hz | |

| Capacity | L | 50 | 50 |

| Total filter area | ㎡ | 32 | 32 |

| Filter composite | EA | 4 | 4 |

| Filtration accuracy | μm | 0.3 | 0.3 |

| Air flow volume | m³/H | 2900 | 3200 |

| Vacuum suction | Kpa | -3.8 | -4.2 |

| Noise | Db | 67 | 68 |

| Air pressure | Mpa | 0.5Mpa<work value<0.6Mpa | |

| Size | MM | 900*850*2250 | |

| Cleaning method | Pulse automatic jet cleaning | ||

Precision laser cutting dust removal

Applicable working conditions

Mainly used for the collection and treatment of floating and suspended dust with a large amount of dust, and small central dust collection systems for multi-station operations; suitable for grinding, cutting, stirring, sandblasting, ceramics, paper, steel, food, plastic, Wood processing and other industries;

Product Features

1. Large air volume and low noise, industrial fans can work continuously for 24 hours;

2.4 automatic pulse cleaning systems for PTFE-coated filter cartridges;

3. It can be matched with small laser cutting machines for dust removal; engraving machines, grinders/belt machines, rubber cutting machines, grinders, milling machines and other machining equipment are matched with dust removal. It is mostly used for the collection and treatment of floating and suspended dust.

4.2.0 sheet metal, independent electrical box, built-in air duct

5. Separate dust collecting bucket with see-through window, you only need to lift and pull the dust collecting bucket to pull out the dust collecting bucket. There is a universal wheel under the dust collecting bucket, which is very convenient for dumping and inhaling materials.

6.68DB noise reduction technology can be placed indoors and outdoors to keep front-line employees away from noise hazards.

| Specification | Unit | YSL-370 | YSL-550 |

| Power | Kw | 3.7 | 5.5 |

| Voltage | V | 380V 50Hz/60Hz | |

| Capacity | L | 50 | 50 |

| Total filter area | ㎡ | 32 | 32 |

| Filter composite | EA | 4 | 4 |

| Filtration accuracy | μm | 0.3 | 0.3 |

| Air flow volume | m³/H | 2900 | 3200 |

| Vacuum suction | Kpa | -3.8 | -4.2 |

| Noise | Db | 67 | 68 |

| Air pressure | Mpa | 0.5Mpa<work value<0.6Mpa | |

| Size | MM | 900*850*2250 | |

| Cleaning method | Pulse automatic jet cleaning | ||

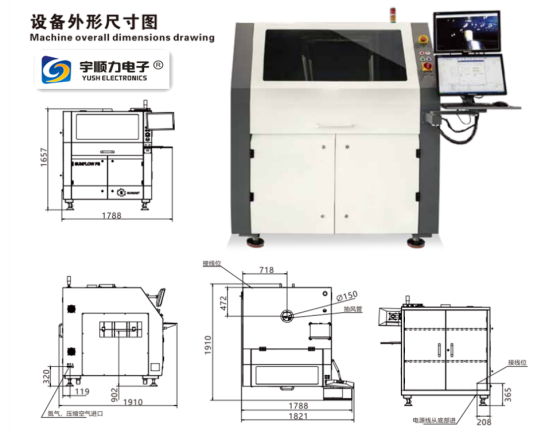

SMT placement machine placement machine parts placement machine

Dual arm magnetic linear LED highspeed pick and place machine

SMT Machine/ High Professional Customization/ Multi Function SMT Line Automatic Factory in China

Best Selling Heller Reflow Soldering Oven Machine For SMT Machine Line

High Speed 6 Heads Multi-functional SMT Pick and Place Machine LED Automatic

Contacts:Eva Liu +8613450659407 +86 13416743702

Tel:+86-512-62751429

Skype:evaliuhuan

Email: caojun@hk-yush.com sales@yushunli.com evaliu@hk-yush.com

Address: Building H, GuoRui Pioneering Park,

No. 1068 Jinyang East Road, Lujia Town, Kunshan,

Suzhou.

Postcode:215331

Dongguan Factory Address: 5th Floor, No.10, Shanquan Road,

Yongtou Village, Chang’an Town, Dongguan City, Guangdong

province,

China.

Postcode:523843