1: Customized system solutions to meet individual needs, flexible options for various production applications.

2: Professional-grade high-quality mechanical design, professional-grade 03015 (metric) solder paste printing process support, 14 years of high-quality machinery manufacturing experience.

3. Easy to operate, minimize downtime for line change. Minimal maintenance requirements and maintenance costs.

4. Use intelligent software tools for process monitoring and tracking at any time.

YSL technical training advantages

1. Provide expertise in system design, operation and process flow

2. Professionals to help you improve production efficiency

3. Comprehensive training plan

4. Personality training and workshops

5. Internal training

Automatic solder paste printing machine Function introduction

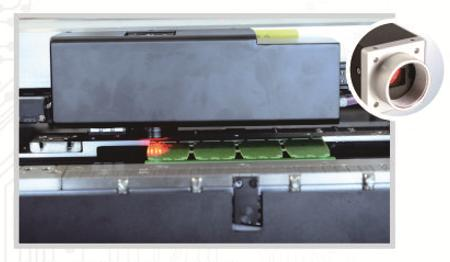

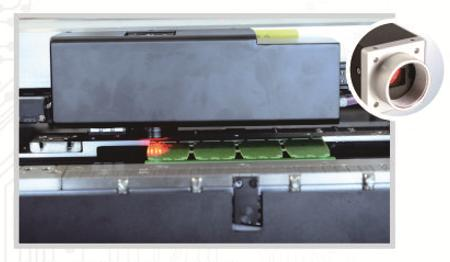

1. CCD digital camera system:

Brand-new optical path system (1.3 million digital camera)--uniform ring light and high-brightness coaxial light, together with infinitely adjustable brightness function, make all types of Mark points can be well identified (including unevenness Mark point), suitable for tin-plated, copper-plated, gold-plated, tin-sprayed, FPC and other types of PCBs with different colors.

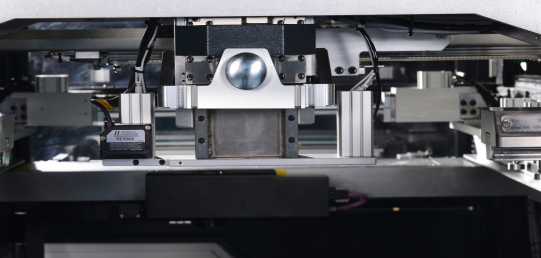

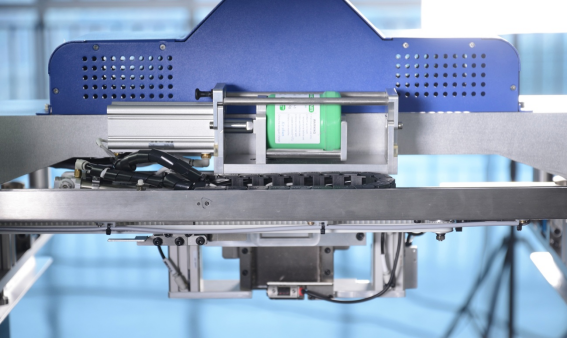

2.Rail positioning system

National utility model invention patent Patent No. (ZL 2005100371991.6), detachable, programmable flexible side clip device, for flexible boards, warped PCBs, and unique top flattening.

Through software programming, it can be automatically stretched without affecting the tin thickness.

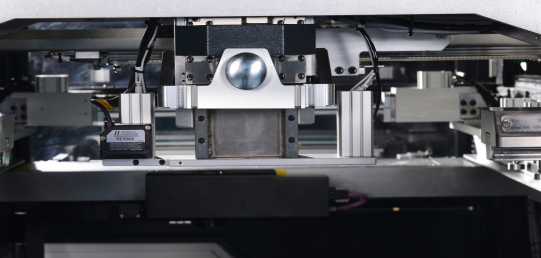

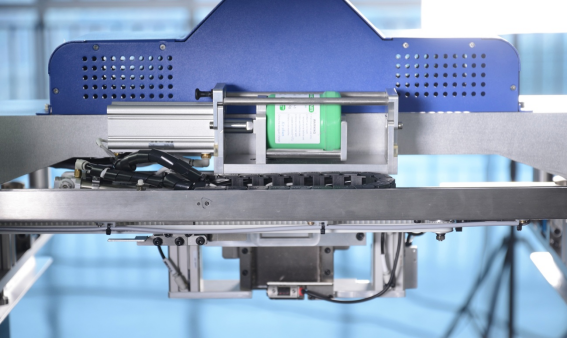

3. Brand new scraper structure design

Through the new scraper structure of the slide rail and the cylinder, the operation stability is improved and the service life is prolonged.

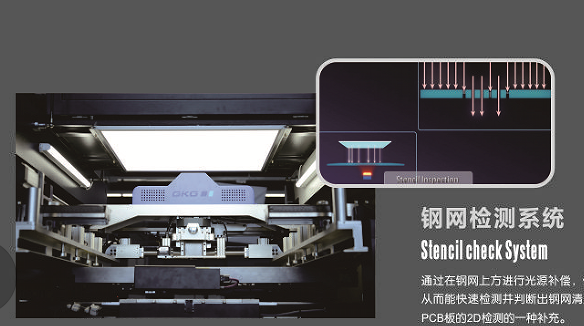

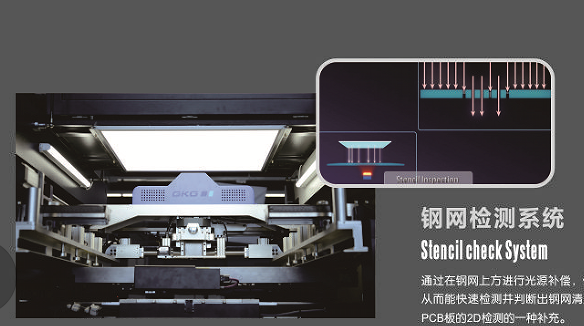

4. Steel mesh detection system

By compensating the light source above the stencil, and using CCD to check the mesh of the stencil in real time, it can quickly detect and judge whether the stencil is blocked after cleaning, and perform automatic cleaning, which is a 2D detection of the PCB board. kind of supplement.

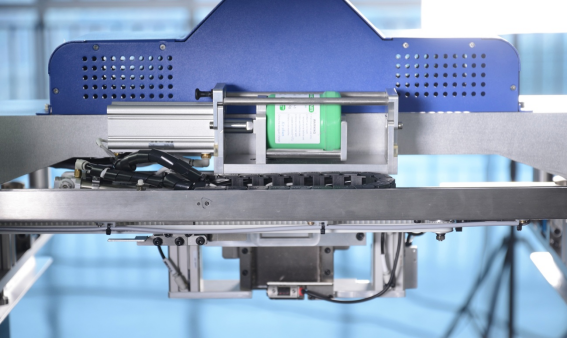

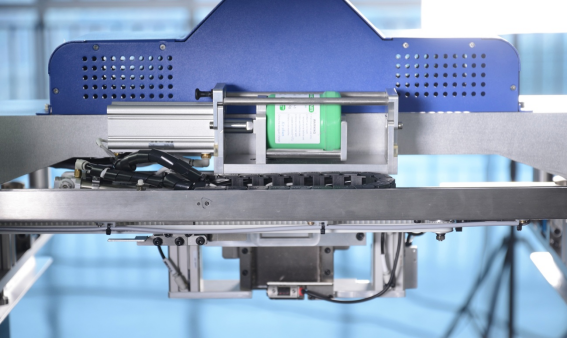

5. Bottle type automatic tinning and automatic solder paste detection function

Automatically add solder paste at regular and fixed points to ensure the quality of solder paste and the amount of solder paste in the stencil. So as to ensure the printing quality of customers and improve productivity.

The sensor manages the amount of solder paste on the stencil, enabling stable quality and long-term continuous printing. Improve productivity

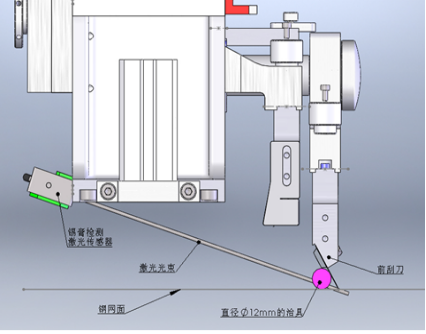

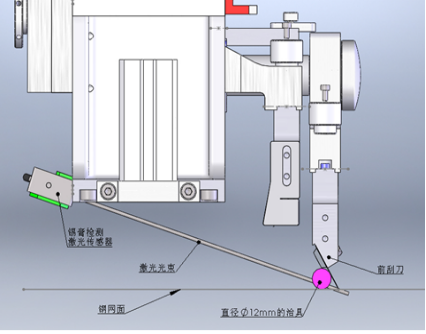

6. Solder paste rolling detection function

1. The stencil solder paste thickness detection system is mainly composed of a laser distance sensor installed behind the squeegee beam.

2. The working principle is mainly that before the machine leaves the factory, we will set the distance from the laser to the sensor. When the diameter of the rolling solder paste is less than ф12mm, the software will alarm and prompt whether to add solder paste or continue production. If the machine simultaneously Configured with automatic tinning function, then when the amount of tin is less than the set value, it will automatically add solder paste (as shown above).

3. The laser distance sensor adopts the built-in CMOS laser sensor of Keyence's amplifier. It adopts a stainless steel casing, which has excellent visibility and is easy to operate. It only needs to press three times to complete the setting, and anyone can easily do it. Adjustments and settings.

7.Bottle type automatic tinning and automatic solder paste detection function

Automatically add solder paste at regular and fixed points to ensure the quality of solder paste and the amount of solder paste in the stencil. So as to ensure the printing quality of customers and improve productivity.

The sensor manages the amount of solder paste on the stencil, enabling stable quality and long-term continuous printing. Improve productivity

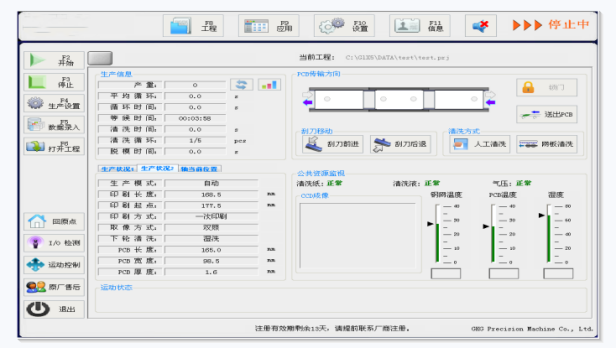

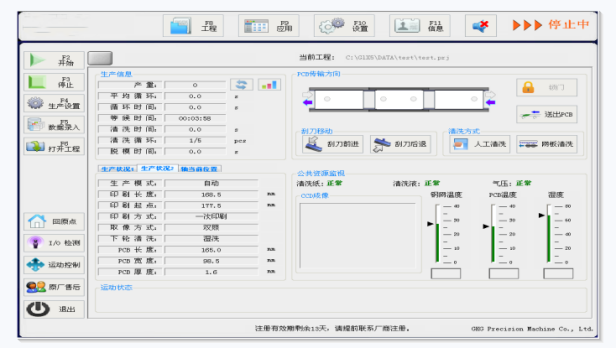

8.New multifunctional interface

concise. Easy to operate. Real-time temperature and humidity monitoring function

9.All screw rods and slider guides of the machine are produced with original foreign products, and imported to ensure accuracy and stability

10.Leading Industry 4.0 Compatibility

Through the automatic upload or output of machine status and parameters, it provides a strong guarantee for customers' Industry 4.0 intelligent production. It can realize the seamless connection with the customer's MES system and achieve high product traceability; intelligent management and control of equipment maintenance.

According to the realization of on-site management, the use rights of engineering personnel at all levels are allocated by themselves.

| Substrate processing | |

| Maximum substrate size (XxY) | 450*340mm |

| Minimum substrate size (XxY) | 50*50mm |

| Substrate thickness dimension | 0.4~6mm |

| Maximum substrate weight | 3Kg |

| Substrate edge clearance | 2.5mm |

| Overboard height | 17mm |

| Transmission height | 900 ± 40mm |

| Transfer speed | 1500mm/s(Max) |

| Transfer method | One-section transport rail |

| Substrate clamping | Automatic retractable upper tablet |

| Flexible side clip | |

| Vacuum suction | |

| Printing parameters | |

| Maximum printing area (XxY) | 450*340mm |

| Printing release (Snap-off) | 0-20mm |

| printing mode | Single or double doctor blade printing |

| Scraper type | Rubber scraper/steel scraper (angle 45/55/60) |

| Printing speed | 6~200mm/sec |

| Printing pressure | 0.5~10Kg |

| Template frame size | 370*370mm~737*737mm |

| Cleaning method | Enhanced vacuum adsorption |

| Dry, wet, vacuum three modes | |

| Cleaning back and forth | |

| Substrate Support Method | Magnetic Thimble |

| Contour block | |

| Manually adjust the jacking platform |

| Image | |

| Image Field of View (FOV) | 8*6mm |

| Datum point type | Standard shape reference point |

| Pad | |

| Hole | |

| Camera system | Vision system for top/bottom imaging |

| Digital camera | |

| Geometry match positioning | |

| Performance | |

| System alignment accuracy and repeatability | ±12.5 microns@6σ,Cpk≥2.0 |

| Actual solder paste placement repeatability | ±18 microns@6σ,Cpk≥2.0 |

| Repeat accuracy of actual solder paste printing position based on third-party test system (CTQ, Germany) verification | |

| Printing cycle | <7.5 sec (excluding printing and cleaning time) |

| Equipment | |

| Power requirements | AC: 220±10%, 50/60HZ, 2.5KW |

| Compressed Air Requirements | 4~6 Kgf/cm2 |

| Air consumption | About 5L/min |

| Working temperature | -20℃~+45℃ |

| Working environment humidity | 30%~60% |

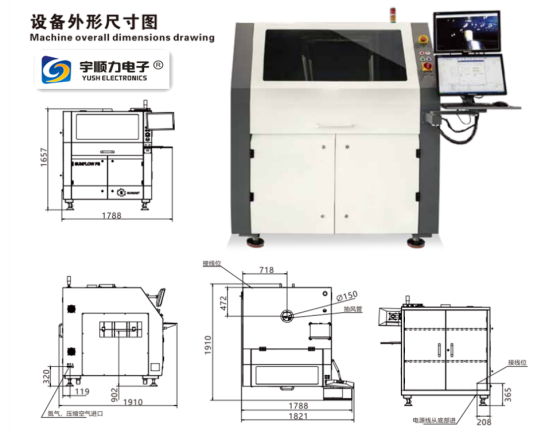

| Machine height (remove tri-color light) | 1510(H)mm |

| Machine length | 1156(L)mm |

| Machine width | 1400(W)mm |

| Machine weight | Approx: about 1000Kg |

Why choose YSL?

Dongguan Yushunli Automation Equipment Co., Ltd. (YSL) can provide the most professional solder paste printing solution system for the electronic manufacturing industry (SMT). As a high-end quality automatic solder paste printing machine manufacturer, it has always led the trend of technological innovation in the assembly and production of electronic components. For a long time, YSL has won the trust of countless "heavyweight" customers in the fields of automotive electronics, medical technology, aerospace technology, industrial electronics and military industry with its excellent quality.

Technology is our passion. YSL pursues excellent product quality and is also committed to providing excellent customer service. From China to Europe, or from Singapore to the United States - we aim to perfect all sales and service networks. Dedicated to provide you with professional support covering the world! Do you have any special inquiries about YSL's printing system, assembly or process? Our responsibility does not stop at sales, after purchasing YSL equipment, we will keep the closest contact with you and respond to all your needs quickly and promptly. We will do our best to ensure on-time delivery and perform installation and maintenance services of the highest standard. In addition, our experts are at your service 24 hours a day, ready to provide you with application support to keep production running smoothly.

1: Customized system solutions to meet individual needs, flexible options for various production applications.

2: Professional-grade high-quality mechanical design, professional-grade 03015 (metric) solder paste printing process support, 14 years of high-quality machinery manufacturing experience.

3. Easy to operate, minimize downtime for line change. Minimal maintenance requirements and maintenance costs.

4. Use intelligent software tools for process monitoring and tracking at any time.

YSL technical training advantages

1. Provide expertise in system design, operation and process flow

2. Professionals to help you improve production efficiency

3. Comprehensive training plan

4. Personality training and workshops

5. Internal training

Automatic solder paste printing machine Function introduction

1. CCD digital camera system:

Brand-new optical path system (1.3 million digital camera)--uniform ring light and high-brightness coaxial light, together with infinitely adjustable brightness function, make all types of Mark points can be well identified (including unevenness Mark point), suitable for tin-plated, copper-plated, gold-plated, tin-sprayed, FPC and other types of PCBs with different colors.

2.Rail positioning system

National utility model invention patent Patent No. (ZL 2005100371991.6), detachable, programmable flexible side clip device, for flexible boards, warped PCBs, and unique top flattening.

Through software programming, it can be automatically stretched without affecting the tin thickness.

3. Brand new scraper structure design

Through the new scraper structure of the slide rail and the cylinder, the operation stability is improved and the service life is prolonged.

4. Steel mesh detection system

By compensating the light source above the stencil, and using CCD to check the mesh of the stencil in real time, it can quickly detect and judge whether the stencil is blocked after cleaning, and perform automatic cleaning, which is a 2D detection of the PCB board. kind of supplement.

5. Bottle type automatic tinning and automatic solder paste detection function

Automatically add solder paste at regular and fixed points to ensure the quality of solder paste and the amount of solder paste in the stencil. So as to ensure the printing quality of customers and improve productivity.

The sensor manages the amount of solder paste on the stencil, enabling stable quality and long-term continuous printing. Improve productivity

6. Solder paste rolling detection function

1. The stencil solder paste thickness detection system is mainly composed of a laser distance sensor installed behind the squeegee beam.

2. The working principle is mainly that before the machine leaves the factory, we will set the distance from the laser to the sensor. When the diameter of the rolling solder paste is less than ф12mm, the software will alarm and prompt whether to add solder paste or continue production. If the machine simultaneously Configured with automatic tinning function, then when the amount of tin is less than the set value, it will automatically add solder paste (as shown above).

3. The laser distance sensor adopts the built-in CMOS laser sensor of Keyence's amplifier. It adopts a stainless steel casing, which has excellent visibility and is easy to operate. It only needs to press three times to complete the setting, and anyone can easily do it. Adjustments and settings.

7.Bottle type automatic tinning and automatic solder paste detection function

Automatically add solder paste at regular and fixed points to ensure the quality of solder paste and the amount of solder paste in the stencil. So as to ensure the printing quality of customers and improve productivity.

The sensor manages the amount of solder paste on the stencil, enabling stable quality and long-term continuous printing. Improve productivity

8.New multifunctional interface

concise. Easy to operate. Real-time temperature and humidity monitoring function

9.All screw rods and slider guides of the machine are produced with original foreign products, and imported to ensure accuracy and stability

10.Leading Industry 4.0 Compatibility

Through the automatic upload or output of machine status and parameters, it provides a strong guarantee for customers' Industry 4.0 intelligent production. It can realize the seamless connection with the customer's MES system and achieve high product traceability; intelligent management and control of equipment maintenance.

According to the realization of on-site management, the use rights of engineering personnel at all levels are allocated by themselves.

| Substrate processing | |

| Maximum substrate size (XxY) | 450*340mm |

| Minimum substrate size (XxY) | 50*50mm |

| Substrate thickness dimension | 0.4~6mm |

| Maximum substrate weight | 3Kg |

| Substrate edge clearance | 2.5mm |

| Overboard height | 17mm |

| Transmission height | 900 ± 40mm |

| Transfer speed | 1500mm/s(Max) |

| Transfer method | One-section transport rail |

| Substrate clamping | Automatic retractable upper tablet |

| Flexible side clip | |

| Vacuum suction | |

| Printing parameters | |

| Maximum printing area (XxY) | 450*340mm |

| Printing release (Snap-off) | 0-20mm |

| printing mode | Single or double doctor blade printing |

| Scraper type | Rubber scraper/steel scraper (angle 45/55/60) |

| Printing speed | 6~200mm/sec |

| Printing pressure | 0.5~10Kg |

| Template frame size | 370*370mm~737*737mm |

| Cleaning method | Enhanced vacuum adsorption |

| Dry, wet, vacuum three modes | |

| Cleaning back and forth | |

| Substrate Support Method | Magnetic Thimble |

| Contour block | |

| Manually adjust the jacking platform |

| Image | |

| Image Field of View (FOV) | 8*6mm |

| Datum point type | Standard shape reference point |

| Pad | |

| Hole | |

| Camera system | Vision system for top/bottom imaging |

| Digital camera | |

| Geometry match positioning | |

| Performance | |

| System alignment accuracy and repeatability | ±12.5 microns@6σ,Cpk≥2.0 |

| Actual solder paste placement repeatability | ±18 microns@6σ,Cpk≥2.0 |

| Repeat accuracy of actual solder paste printing position based on third-party test system (CTQ, Germany) verification | |

| Printing cycle | <7.5 sec (excluding printing and cleaning time) |

| Equipment | |

| Power requirements | AC: 220±10%, 50/60HZ, 2.5KW |

| Compressed Air Requirements | 4~6 Kgf/cm2 |

| Air consumption | About 5L/min |

| Working temperature | -20℃~+45℃ |

| Working environment humidity | 30%~60% |

| Machine height (remove tri-color light) | 1510(H)mm |

| Machine length | 1156(L)mm |

| Machine width | 1400(W)mm |

| Machine weight | Approx: about 1000Kg |

Why choose YSL?

Dongguan Yushunli Automation Equipment Co., Ltd. (YSL) can provide the most professional solder paste printing solution system for the electronic manufacturing industry (SMT). As a high-end quality automatic solder paste printing machine manufacturer, it has always led the trend of technological innovation in the assembly and production of electronic components. For a long time, YSL has won the trust of countless "heavyweight" customers in the fields of automotive electronics, medical technology, aerospace technology, industrial electronics and military industry with its excellent quality.

Technology is our passion. YSL pursues excellent product quality and is also committed to providing excellent customer service. From China to Europe, or from Singapore to the United States - we aim to perfect all sales and service networks. Dedicated to provide you with professional support covering the world! Do you have any special inquiries about YSL's printing system, assembly or process? Our responsibility does not stop at sales, after purchasing YSL equipment, we will keep the closest contact with you and respond to all your needs quickly and promptly. We will do our best to ensure on-time delivery and perform installation and maintenance services of the highest standard. In addition, our experts are at your service 24 hours a day, ready to provide you with application support to keep production running smoothly.

SMT placement machine placement machine parts placement machine

Dual arm magnetic linear LED highspeed pick and place machine

SMT Machine/ High Professional Customization/ Multi Function SMT Line Automatic Factory in China

Best Selling Heller Reflow Soldering Oven Machine For SMT Machine Line

High Speed 6 Heads Multi-functional SMT Pick and Place Machine LED Automatic

Contacts:Eva Liu +8613450659407 +86 13416743702

Tel:+86-512-62751429

Skype:evaliuhuan

Email: caojun@hk-yush.com sales@yushunli.com evaliu@hk-yush.com

Address: Building H, GuoRui Pioneering Park,

No. 1068 Jinyang East Road, Lujia Town, Kunshan,

Suzhou.

Postcode:215331

Dongguan Factory Address: 5th Floor, No.10, Shanquan Road,

Yongtou Village, Chang’an Town, Dongguan City, Guangdong

province,

China.

Postcode:523843