Technical requirements:

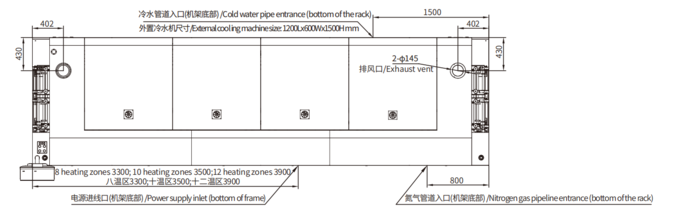

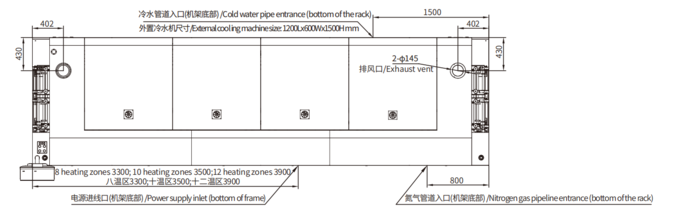

1, The customer to install control valve to control the import and export of the exhaust volume up to 145;

2,Each up to 145 entrance hole exhaust volume control in 15M³>/min;

3, The main power supply: 3 380V diameter AC five wire, the main power line diameter of more than 35mm².

Product Features

1.Durable, interchangeable double-sided rails and special hardening;

2.Adopt stainless steel belt chain with guard, anti-clamp, practical and reliable;

3.New flux recovery system, full modular design, convenient and quick maintenance, reduce maintenance time and cost;

4.Patented hot air system, more efficient, faster heat compensation;

5.New furnace structure design, multi-layer heat insulation, effectively reduce the working environment temperature.

Technical Parameters

| S series reflow oven main specifications | ||||||

| Model No | YSL-08AS/ YSL-08NS | YSL-10AS/ YSL-10NS | YSL-12AS/ YSL-12NS | YSL-08DAS/ YSL-08DNS | YSL-10DAS/ YSL-10DNS | YSL-12DAS/ YSL-12DNS |

| Heating System | ||||||

| Heating Zone | 8 heating zones,16 heating modules | 10 heating zones,20 heating modules | 12 heating zones, 24 heating modules | 8 heating zones,16 heating modules | 10 heating zones,20 heating modules | 12 heating zones,24 heating modules |

| Heating Length | 3120mm | 3870mm | 4635mm | 3120mm | 3870mm | 4635mm |

| Cooling Type | Three cooling zones:forced air cooling/water cooling | |||||

| Outlet Exhaust Diameter,valume | 2-145,Exhaust demand 15m³/min x2 | |||||

| Conveyor System | ||||||

| Product Width | Min50mm-Max400mm | Min50mm-Max270mm(Dual track at the same time) Min50mm-Max500mm(Dual-track alone) | ||||

| Conveying Direction | L→R,R→L | |||||

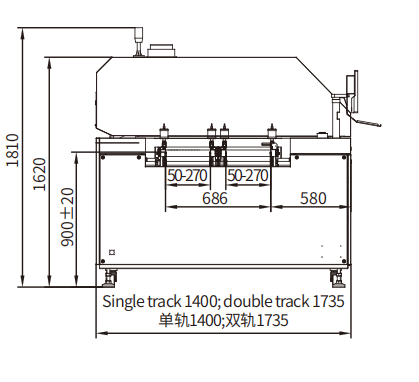

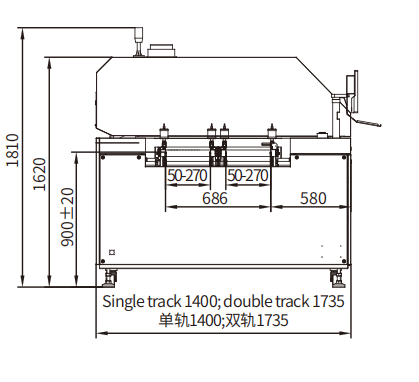

| Inlet Height | 900±20mm | |||||

| Fixed Rail Side | Front rail Fixed (Option:Rear Rail Fixed) | Front and Rear Rails Fixed,central two rails are movavle | ||||

| ConveyorType | Chain+mesh belt synchronous trans mission | |||||

| Cmponent Height | Clearance based on the rail: above 30mm,below 25mm | |||||

| Conveying Speed | 300mm-2000mm/min | |||||

| Control System | ||||||

| Power Supply | AC30 5W 380V 50/60HZ | |||||

| Total Power | 59KW | 73KW | 91KW | 70KW | 89KW | 108KW |

| Start Up Power | 30KW | 35KW | 40KW | 35KW | 40KW | 45KW |

| Running Power | 7.5KW | 9.5KW | 11.5KW | 10KW | 11.5KW | 13KW |

| Temperature Range | Room temp to 320℃ | |||||

| Control type | PC+PLC Control system | |||||

| Rail Width Adjusting Mode | Electric+Manual | |||||

| Temp Control accuracy | ±1℃ | |||||

| PCB Temp Deviation | ±1℃ | ±2℃ | ||||

| Data Store | Process Data and status stotage | |||||

| Power Outage Protection | Equipped with UPS | |||||

| Operation Interface | Windows Chinese simplified, English online free switching | |||||

| General | ||||||

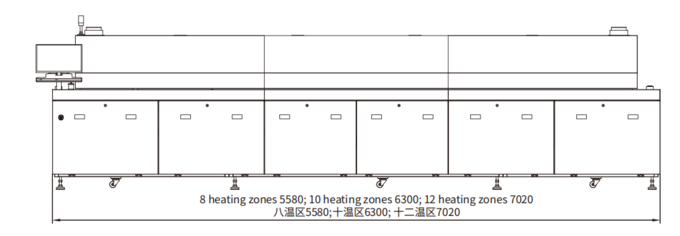

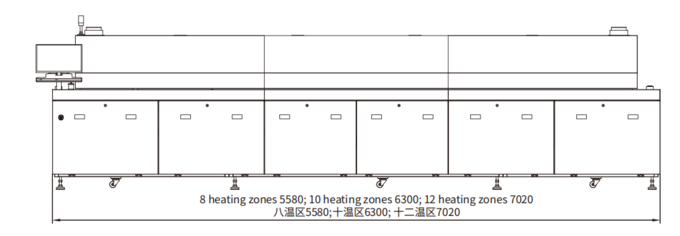

| Dimension(L*W*H) | 5580x1450x1620mm | 6300x1450x1620mm | 7020x 1450x1620mm | 5580x1735x1620mm | 6300x1735x1620mm | 7020x1735x1620mm |

| Weight | 2200-2400kg | 2600-2800kg | 3000-3200kg | 2700-2900kg | 3000-3200kg | 3300-3500kg |

| Color | Bright wrinkled white | |||||

Technical requirements:

1, The customer to install control valve to control the import and export of the exhaust volume up to 145;

2,Each up to 145 entrance hole exhaust volume control in 15M³>/min;

3, The main power supply: 3 380V diameter AC five wire, the main power line diameter of more than 35mm².

Product Features

1.Durable, interchangeable double-sided rails and special hardening;

2.Adopt stainless steel belt chain with guard, anti-clamp, practical and reliable;

3.New flux recovery system, full modular design, convenient and quick maintenance, reduce maintenance time and cost;

4.Patented hot air system, more efficient, faster heat compensation;

5.New furnace structure design, multi-layer heat insulation, effectively reduce the working environment temperature.

Technical Parameters

| S series reflow oven main specifications | ||||||

| Model No | YSL-08AS/ YSL-08NS | YSL-10AS/ YSL-10NS | YSL-12AS/ YSL-12NS | YSL-08DAS/ YSL-08DNS | YSL-10DAS/ YSL-10DNS | YSL-12DAS/ YSL-12DNS |

| Heating System | ||||||

| Heating Zone | 8 heating zones,16 heating modules | 10 heating zones,20 heating modules | 12 heating zones, 24 heating modules | 8 heating zones,16 heating modules | 10 heating zones,20 heating modules | 12 heating zones,24 heating modules |

| Heating Length | 3120mm | 3870mm | 4635mm | 3120mm | 3870mm | 4635mm |

| Cooling Type | Three cooling zones:forced air cooling/water cooling | |||||

| Outlet Exhaust Diameter,valume | 2-145,Exhaust demand 15m³/min x2 | |||||

| Conveyor System | ||||||

| Product Width | Min50mm-Max400mm | Min50mm-Max270mm(Dual track at the same time) Min50mm-Max500mm(Dual-track alone) | ||||

| Conveying Direction | L→R,R→L | |||||

| Inlet Height | 900±20mm | |||||

| Fixed Rail Side | Front rail Fixed (Option:Rear Rail Fixed) | Front and Rear Rails Fixed,central two rails are movavle | ||||

| ConveyorType | Chain+mesh belt synchronous trans mission | |||||

| Cmponent Height | Clearance based on the rail: above 30mm,below 25mm | |||||

| Conveying Speed | 300mm-2000mm/min | |||||

| Control System | ||||||

| Power Supply | AC30 5W 380V 50/60HZ | |||||

| Total Power | 59KW | 73KW | 91KW | 70KW | 89KW | 108KW |

| Start Up Power | 30KW | 35KW | 40KW | 35KW | 40KW | 45KW |

| Running Power | 7.5KW | 9.5KW | 11.5KW | 10KW | 11.5KW | 13KW |

| Temperature Range | Room temp to 320℃ | |||||

| Control type | PC+PLC Control system | |||||

| Rail Width Adjusting Mode | Electric+Manual | |||||

| Temp Control accuracy | ±1℃ | |||||

| PCB Temp Deviation | ±1℃ | ±2℃ | ||||

| Data Store | Process Data and status stotage | |||||

| Power Outage Protection | Equipped with UPS | |||||

| Operation Interface | Windows Chinese simplified, English online free switching | |||||

| General | ||||||

| Dimension(L*W*H) | 5580x1450x1620mm | 6300x1450x1620mm | 7020x 1450x1620mm | 5580x1735x1620mm | 6300x1735x1620mm | 7020x1735x1620mm |

| Weight | 2200-2400kg | 2600-2800kg | 3000-3200kg | 2700-2900kg | 3000-3200kg | 3300-3500kg |

| Color | Bright wrinkled white | |||||

Contacts:Eva Liu +8613450659407 +86 13416743702

Tel:+86-512-62751429

Skype:evaliuhuan

Email: caojun@hk-yush.com sales@yushunli.com evaliu@hk-yush.com

Address: Building H, GuoRui Pioneering Park,

No. 1068 Jinyang East Road, Lujia Town, Kunshan,

Suzhou.

Postcode:215331

Dongguan Factory Address: 5th Floor, No.10, Shanquan Road,

Yongtou Village, Chang’an Town, Dongguan City, Guangdong

province,

China.

Postcode:523843