Product introduction

1. Connect with the online plate distributor or other equipment, load the divided PCB into the Tray by means of servo load shifting and grasping.

2. Suitable for Tray of different sizes; With empty Tray automatic supply, full Tray automatic collection stack function.

3. Suitable for Tray of different sizes and heights; Tray stack height 400mm.

4. The whole machine adopts microcomputer control, LCD operation interface; Can store more than 10 kinds of operation program.

5. All the grasping mechanism adopts servomotor module to realize long stroke and smooth load shifting.

6. Stepper brake motor control of pallet load shifting mechanism; Tray width can be adjusted, equipped with tray correction function.

7. Four groups of adsorption units are configured on the module of taking the plate; Each group of units vacuum independent control and detection, non-interference.

8. Each group of adsorption units can rotate 0-180° according to product and placement requirements.

Machine Application

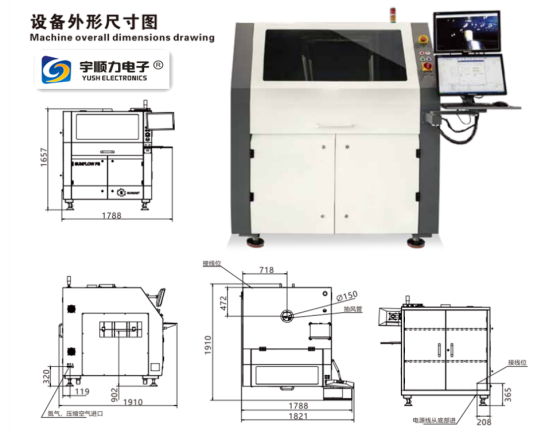

Product outline size drawing

Product performance characteristics

Lift and shift module Vacuum suction plate module

Tray automatic change module Tray lifting platform

Applicable product specification

| Device name | Tray Plate Receiver |

| Suitable for maximum size of subboard | 350*300mm |

| Suitable for Tray size | 180*250mm(min) ~ 450*350mm(max) |

| Tray stack height | 400mm |

| Tray is carried | Manual labor |

| Take-up direction | Left-right/right-left |

| Feeding and discharging method | Vacuum sucker adsorption transfer load |

| Number of feeding sucker modules | 4 groups (independent control) |

| Feeding and discharging control mode | X/Y/Z/R axis servo motor control |

| Tray lifting and shifting mode | Stepper motor (brake) |

| Load moving speed (maximum) | 800mm/min |

| Load shifting repetition accuracy | The 0.05 mm |

| Take-and-drop efficiency | 12-15 seconds /4 small pcs |

| PCB mobile function | Translation, rotation 90 degrees, rotation 180 degrees |

| Control system | Microcomputer (PLC) /PC |

| Operating interface | Touch Chinese interface |

| Power supply specification | AC220V 50/60 Hz single phase |

| Compressed air | 0.6MPA (with filter included) |

| Overall dimension | About 1500(W)*1475(D)*1800(H)mm |

| weight | 450Kg |

| power | 3.2 KW |

Product introduction

1. Connect with the online plate distributor or other equipment, load the divided PCB into the Tray by means of servo load shifting and grasping.

2. Suitable for Tray of different sizes; With empty Tray automatic supply, full Tray automatic collection stack function.

3. Suitable for Tray of different sizes and heights; Tray stack height 400mm.

4. The whole machine adopts microcomputer control, LCD operation interface; Can store more than 10 kinds of operation program.

5. All the grasping mechanism adopts servomotor module to realize long stroke and smooth load shifting.

6. Stepper brake motor control of pallet load shifting mechanism; Tray width can be adjusted, equipped with tray correction function.

7. Four groups of adsorption units are configured on the module of taking the plate; Each group of units vacuum independent control and detection, non-interference.

8. Each group of adsorption units can rotate 0-180° according to product and placement requirements.

Machine Application

Product outline size drawing

Product performance characteristics

Lift and shift module Vacuum suction plate module

Tray automatic change module Tray lifting platform

Applicable product specification

| Device name | Tray Plate Receiver |

| Suitable for maximum size of subboard | 350*300mm |

| Suitable for Tray size | 180*250mm(min) ~ 450*350mm(max) |

| Tray stack height | 400mm |

| Tray is carried | Manual labor |

| Take-up direction | Left-right/right-left |

| Feeding and discharging method | Vacuum sucker adsorption transfer load |

| Number of feeding sucker modules | 4 groups (independent control) |

| Feeding and discharging control mode | X/Y/Z/R axis servo motor control |

| Tray lifting and shifting mode | Stepper motor (brake) |

| Load moving speed (maximum) | 800mm/min |

| Load shifting repetition accuracy | The 0.05 mm |

| Take-and-drop efficiency | 12-15 seconds /4 small pcs |

| PCB mobile function | Translation, rotation 90 degrees, rotation 180 degrees |

| Control system | Microcomputer (PLC) /PC |

| Operating interface | Touch Chinese interface |

| Power supply specification | AC220V 50/60 Hz single phase |

| Compressed air | 0.6MPA (with filter included) |

| Overall dimension | About 1500(W)*1475(D)*1800(H)mm |

| weight | 450Kg |

| power | 3.2 KW |

SMT placement machine placement machine parts placement machine

Dual arm magnetic linear LED highspeed pick and place machine

SMT Machine/ High Professional Customization/ Multi Function SMT Line Automatic Factory in China

Best Selling Heller Reflow Soldering Oven Machine For SMT Machine Line

High Speed 6 Heads Multi-functional SMT Pick and Place Machine LED Automatic

Contacts:Eva Liu +8613450659407 +86 13416743702

Tel:+86-512-62751429

Skype:evaliuhuan

Email: caojun@hk-yush.com sales@yushunli.com evaliu@hk-yush.com

Address: Building H, GuoRui Pioneering Park,

No. 1068 Jinyang East Road, Lujia Town, Kunshan,

Suzhou.

Postcode:215331

Dongguan Factory Address: 5th Floor, No.10, Shanquan Road,

Yongtou Village, Chang’an Town, Dongguan City, Guangdong

province,

China.

Postcode:523843