Product introduction

1. Mainly applicable to automotive electronics, mobile phones, digital cameras, 3G network cards and other industries of small board, multi-link board, shaped board cutting.

2. The whole machine adopts servo module, vision, IPC combined working mode, suitable for high precision, high efficiency of the board operation.

3. Can cut straight, L, U, round, arc and other special-shaped PCB board.

4. The main shaft adopts German high-speed spindle, equipped with automatic milling cutter, automatic cutter breaking (cutting off) detection system, self-check function after cutting and automatic edge searching programming function.

5. Upper/lower dust collection mode; The upper dust collection adopts floating brush to follow the suction to ensure better dust removal effect after cutting.

6. Milling cutter adopts right-handed milling cutter, which can be set according to PCBA thickness, saving the cost of milling cutter usage.

7. Programming method adopts the whole board CCD camera to take photos and scan programming, reducing the programming and adjustment time, to ensure the quality of the board; Gerber import programming and off-line programming can also be used.

8. The operating system adopts Win10 legitimate operating system and PC software control program; Software independent research and development, can be free for life unlimited upgrade.

9. Open MES system connection port and BAR CODE scanning port function free of charge.

10. There are two kinds of plate discharging modes: pallet discharging and belt discharging. Can be connected to the pendulum machine.

Machine Application

Product connection diagram

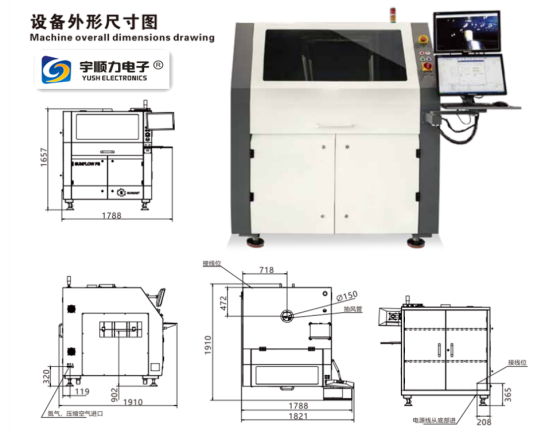

Product dimensions

Optional function

| Number | Name | Function |

| 1 | Bar code camera | Used to read the bar code on the PCB |

| 2 | Laser height module | Used to check whether the PCB is properly placed |

| 3 | CCD | Used to read the bar code on the PCB |

| 4 | Anti-riot dust collector | Prevent the collected dust from exploding |

| 5 | Fingerprint identification module | Operating log-in permits for different personnel |

| 6 | Tool diameter test module | CCD camera is used to detect the diameter of the milling cutter to prevent the wrong use |

Product performance characteristics

• Equipped with automatic tool changing mechanism to avoid industrial injury and misoperation.

• It has the function of automatic cutting and cutting detection.

• Z-axis has automatic compensation setting to automatically adjust the depth of the milling cutter

SYCOTEC (Germany)/KAVOTEC (Taiwan) high speed spindle

• Rotational speed:60000-80000rpm (max)

• Power:500W (max)

•Accuracy:lum

Entry track

• With automatic width adjustment function.

• With automatic clamping and limiting device.

• Connect to front-end devices to deliver 900±50mmo height

• Board edge W5min.

Split-plate platform

• Single working platform.

• Automatic cover plate when in place.

• Use servo modules for load shifting and positioning.

• The suckers can be replaced modulatively.

Take and release module

• Put the PCB into the sub-board platform by adsorption on the left side, and put the divided PCB into the back belt line by absorption on the right side.

• Different types of sucker modules can be made for quick modular replacement.

• Optional jaw type taking and discharging materials according to customer needs.

Discharge platform

• The segmented PCB is connected to the rear assembly line by belt transfer.

• Can be changed to pallet type according to customer requirements, convenient to connect with the back end of the plate receiver, testing machine, tin furnace and other equipment.

Counterpoint system

• CCD is used to automatically identify mark points for alignment, to ensure the cutting path and ensure the cutting accuracy.

• It can recognize the whole board mark or single board mark.

Programming system

• Programming mode mainly adopts the quick programming after the whole board scanning, and can also quickly modify the cutting path.

• You can edit offline programs through AUTO CAD or DXF files, effectively saving online programming time

Suitable for PCBA segmentation of any shape

Milling cutter specification

1. Right-handed milling cutter, milling cutter rotation direction and draft direction is consistent.

2. Carbon alloy milling cutter head:

a. Total length: 38.2 ± 0.30mm;

b. Handle diameter: 3.165 mm

c. Length of cutting section: 8± 0.50mm

d. Cutting section diameter: 0.8-3.0mm

Floating brush

Optimize the vacuuming module to improve the vacuum negative pressure and ensure the vacuuming effect

Dust collector

• The upper and lower vacuuming modes are optional, with the standard 4.5KW (6HP) upper dust collection and 3.75KW(5HP) lower dust collection.

• Used to collect dust and debris in the PCB cutting process.

• Internal use of high horsepower motor and high efficiency fan, high dust collection efficiency, and can minimize the dust adhesion in the cutting product.

MES system

• Open MES docking port and BAR CODE scanning port functions free of charge for life.

• To provide product traceability, equipment status, production data collection management in the central information personnel.

Operating interface

• Simple operation interface, 9 steps covering all operation processes.

• Clear classification of functional projects, simple setting of milling cutter/fixture parameters

• Provide four levels of permission, and set operation permission according to the job position.

• The "History window" can display and query operation records

Operation records and machine alarm records shall be kept by day. Operator, technician operations can be traced.

Applicable product specification

| Lead plane | |

| XYZ shaft drive mode | Panasonic AC servo motor |

| Number of stored knives | 8PCS |

| Program teaching mode | CCD color image intuitive instruction input |

| Safety protection | Safety grating protection |

| Cutter detection | Standard arrangement |

| Program backup | USB |

| Operating system | Windows 10 |

| Control mode | Precision multi-axis control system |

| Operating interface | Monitor + keyboard + mouse |

| PCB loading/unloading | Automatic plate placing and taking |

| Power supply specification | AC220V 50/60HZ 4KW (single-phase) |

| Air source specification | 0.5Mpa |

| Overall dimension | 2284mm(L)X1605mm(D)X1716mm(H) |

| Weight | 930KG |

| Dust collector | ||

| Standard model | YS300L (Dust collection) | YS200L (Next dust collection) |

| Power supply specification | AC380V 50/60HZ | AC380V 50/60HZ |

| Output power | 4. 5KW (6HP) | 3. 7KW (5HP) |

| Inlet wind speed | 29m/s | 62m/s |

| Vacuum value | 310mbar | 260mbar |

| Inlet/outlet diameter | D50mm/D125mm | D150mm/D200mm |

| Filter bag material/grade/size | Polyester/HEPA/W610*L750mm | Polyester/PTFE/D120*L600mm |

| Bucket capacity | D400*H600mm | W540*D600*H140mm |

| Motor protection class | IP54 | IP54 |

| noise | <78dp | <79dp |

| weight | 130kg | 220kg |

| Overall dimension | 1050mm(W)*530mm(D)*1200mm(H) | 888mm(W)*738mm(D)*1772mm(H) |

Product introduction

1. Mainly applicable to automotive electronics, mobile phones, digital cameras, 3G network cards and other industries of small board, multi-link board, shaped board cutting.

2. The whole machine adopts servo module, vision, IPC combined working mode, suitable for high precision, high efficiency of the board operation.

3. Can cut straight, L, U, round, arc and other special-shaped PCB board.

4. The main shaft adopts German high-speed spindle, equipped with automatic milling cutter, automatic cutter breaking (cutting off) detection system, self-check function after cutting and automatic edge searching programming function.

5. Upper/lower dust collection mode; The upper dust collection adopts floating brush to follow the suction to ensure better dust removal effect after cutting.

6. Milling cutter adopts right-handed milling cutter, which can be set according to PCBA thickness, saving the cost of milling cutter usage.

7. Programming method adopts the whole board CCD camera to take photos and scan programming, reducing the programming and adjustment time, to ensure the quality of the board; Gerber import programming and off-line programming can also be used.

8. The operating system adopts Win10 legitimate operating system and PC software control program; Software independent research and development, can be free for life unlimited upgrade.

9. Open MES system connection port and BAR CODE scanning port function free of charge.

10. There are two kinds of plate discharging modes: pallet discharging and belt discharging. Can be connected to the pendulum machine.

Machine Application

Product connection diagram

Product dimensions

Optional function

| Number | Name | Function |

| 1 | Bar code camera | Used to read the bar code on the PCB |

| 2 | Laser height module | Used to check whether the PCB is properly placed |

| 3 | CCD | Used to read the bar code on the PCB |

| 4 | Anti-riot dust collector | Prevent the collected dust from exploding |

| 5 | Fingerprint identification module | Operating log-in permits for different personnel |

| 6 | Tool diameter test module | CCD camera is used to detect the diameter of the milling cutter to prevent the wrong use |

Product performance characteristics

• Equipped with automatic tool changing mechanism to avoid industrial injury and misoperation.

• It has the function of automatic cutting and cutting detection.

• Z-axis has automatic compensation setting to automatically adjust the depth of the milling cutter

SYCOTEC (Germany)/KAVOTEC (Taiwan) high speed spindle

• Rotational speed:60000-80000rpm (max)

• Power:500W (max)

•Accuracy:lum

Entry track

• With automatic width adjustment function.

• With automatic clamping and limiting device.

• Connect to front-end devices to deliver 900±50mmo height

• Board edge W5min.

Split-plate platform

• Single working platform.

• Automatic cover plate when in place.

• Use servo modules for load shifting and positioning.

• The suckers can be replaced modulatively.

Take and release module

• Put the PCB into the sub-board platform by adsorption on the left side, and put the divided PCB into the back belt line by absorption on the right side.

• Different types of sucker modules can be made for quick modular replacement.

• Optional jaw type taking and discharging materials according to customer needs.

Discharge platform

• The segmented PCB is connected to the rear assembly line by belt transfer.

• Can be changed to pallet type according to customer requirements, convenient to connect with the back end of the plate receiver, testing machine, tin furnace and other equipment.

Counterpoint system

• CCD is used to automatically identify mark points for alignment, to ensure the cutting path and ensure the cutting accuracy.

• It can recognize the whole board mark or single board mark.

Programming system

• Programming mode mainly adopts the quick programming after the whole board scanning, and can also quickly modify the cutting path.

• You can edit offline programs through AUTO CAD or DXF files, effectively saving online programming time

Suitable for PCBA segmentation of any shape

Milling cutter specification

1. Right-handed milling cutter, milling cutter rotation direction and draft direction is consistent.

2. Carbon alloy milling cutter head:

a. Total length: 38.2 ± 0.30mm;

b. Handle diameter: 3.165 mm

c. Length of cutting section: 8± 0.50mm

d. Cutting section diameter: 0.8-3.0mm

Floating brush

Optimize the vacuuming module to improve the vacuum negative pressure and ensure the vacuuming effect

Dust collector

• The upper and lower vacuuming modes are optional, with the standard 4.5KW (6HP) upper dust collection and 3.75KW(5HP) lower dust collection.

• Used to collect dust and debris in the PCB cutting process.

• Internal use of high horsepower motor and high efficiency fan, high dust collection efficiency, and can minimize the dust adhesion in the cutting product.

MES system

• Open MES docking port and BAR CODE scanning port functions free of charge for life.

• To provide product traceability, equipment status, production data collection management in the central information personnel.

Operating interface

• Simple operation interface, 9 steps covering all operation processes.

• Clear classification of functional projects, simple setting of milling cutter/fixture parameters

• Provide four levels of permission, and set operation permission according to the job position.

• The "History window" can display and query operation records

Operation records and machine alarm records shall be kept by day. Operator, technician operations can be traced.

Applicable product specification

| Lead plane | |

| XYZ shaft drive mode | Panasonic AC servo motor |

| Number of stored knives | 8PCS |

| Program teaching mode | CCD color image intuitive instruction input |

| Safety protection | Safety grating protection |

| Cutter detection | Standard arrangement |

| Program backup | USB |

| Operating system | Windows 10 |

| Control mode | Precision multi-axis control system |

| Operating interface | Monitor + keyboard + mouse |

| PCB loading/unloading | Automatic plate placing and taking |

| Power supply specification | AC220V 50/60HZ 4KW (single-phase) |

| Air source specification | 0.5Mpa |

| Overall dimension | 2284mm(L)X1605mm(D)X1716mm(H) |

| Weight | 930KG |

| Dust collector | ||

| Standard model | YS300L (Dust collection) | YS200L (Next dust collection) |

| Power supply specification | AC380V 50/60HZ | AC380V 50/60HZ |

| Output power | 4. 5KW (6HP) | 3. 7KW (5HP) |

| Inlet wind speed | 29m/s | 62m/s |

| Vacuum value | 310mbar | 260mbar |

| Inlet/outlet diameter | D50mm/D125mm | D150mm/D200mm |

| Filter bag material/grade/size | Polyester/HEPA/W610*L750mm | Polyester/PTFE/D120*L600mm |

| Bucket capacity | D400*H600mm | W540*D600*H140mm |

| Motor protection class | IP54 | IP54 |

| noise | <78dp | <79dp |

| weight | 130kg | 220kg |

| Overall dimension | 1050mm(W)*530mm(D)*1200mm(H) | 888mm(W)*738mm(D)*1772mm(H) |

SMT placement machine placement machine parts placement machine

Dual arm magnetic linear LED highspeed pick and place machine

SMT Machine/ High Professional Customization/ Multi Function SMT Line Automatic Factory in China

Best Selling Heller Reflow Soldering Oven Machine For SMT Machine Line

High Speed 6 Heads Multi-functional SMT Pick and Place Machine LED Automatic

Contacts:Eva Liu +8613450659407 +86 13416743702

Tel:+86-512-62751429

Skype:evaliuhuan

Email: caojun@hk-yush.com sales@yushunli.com evaliu@hk-yush.com

Address: Building H, GuoRui Pioneering Park,

No. 1068 Jinyang East Road, Lujia Town, Kunshan,

Suzhou.

Postcode:215331

Dongguan Factory Address: 5th Floor, No.10, Shanquan Road,

Yongtou Village, Chang’an Town, Dongguan City, Guangdong

province,

China.

Postcode:523843