| SE series reflow oven main specifications (Daul Rails) | |||||||||

| Model No | YSL-708AHSE Daul Rails | YSL-708HSE Daul Rails | YSL-708NHSE Daul Rails | YSL-710AHSE Daul Rails | YSL-710HSE Daul Rails | YSL-710NHSE Daul Rails | YSL-712AHSE Daul Rails | YSL-712HSE Daul Rails | YSL-712NHSE Daul Rails |

| Heating System | |||||||||

| Heating Zone | 8 heating zones, 16 heating modules | 10 heating zones, 20 heating modules | 12 heating zones, 24 heating modules | ||||||

| Heating Length | 2950mm | 3670mm | 4350mm | ||||||

| Cooling Type | Double cooling:enforced air cooling/water cooling(Optional:three cooling zones) | ||||||||

| Outlet Exhaust Diameter valume | 2-145,Exhaust demand 15m³/min*2 | ||||||||

| Conveyor System | |||||||||

| Product width | Min50mm-Max270mm(simultaneously)/(Optional:Simultaneous overboard max300mm) | ||||||||

| Min50mm-Max500mm(single track)/(Optional: single track over board max550mm) | |||||||||

| Conveying Direction | L→R,R→L | ||||||||

| Inlet Height | 900±20mm | ||||||||

| Fixed Rail Side | Front and Rear End Rails Fixed,2 Central Rail adjustable | ||||||||

| Conveyor Type | Chain+mesh belt synchronous transmission | ||||||||

| Cmponent Height | Clearance based on the rail:above 30mm,below 20mm | ||||||||

| Conveying speed | 300mm-1500mm/min(Option:Double Speed) | ||||||||

| Control System | |||||||||

| Power Supply | AC3 5W 380V 50/60Hz | ||||||||

| Total Power | 70KW | 89KW | 108KW | ||||||

| Start Up Power | 35KW | 40KW | 42KW | ||||||

| Running Power | 10KW | 11.5KW | 13KW | ||||||

| Temperature Range | Room temperature to 320℃ | ||||||||

| Control type | PC+PLC Control system | ||||||||

| Rail Width Adjusting Mode | Electric+Manual | ||||||||

| Temp Control accuracy | ±1℃ | ||||||||

| PCB Temp Deviation | ±2℃ | ||||||||

| Data Storage | Process Data and status stotage | ||||||||

| Power Outage Protection | Equipped with UPS | ||||||||

| Operation interface | Windows Chinese simplified,English online free switching | ||||||||

| General | |||||||||

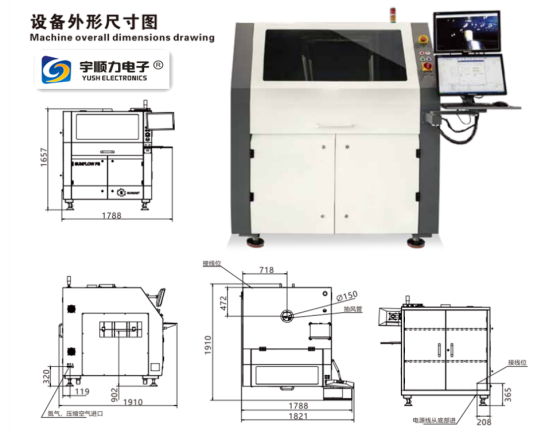

| Dimension(L*W*H) | 5055*1610*1515mm | 5775*1610*1515mm | 6495*1610*1515mm | ||||||

| Weight | 2500-2700KG | 2900-3100KG | 3300-3500KG | ||||||

| Color | Bright wrinkled white | ||||||||

Manual+electric width adjustment structure design, equipped with emergency manual transmission structure in case of preventing PCB burned when power off.

Conveyor system:stable and reliable anti-deformation structure design.

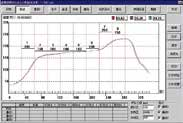

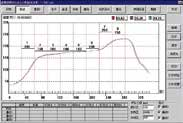

Built-in temperature profile test function, virtual simulation function, save setting time.

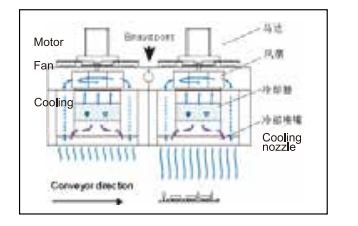

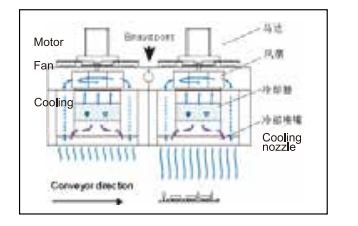

Two cooling zones

Cooling system, new patented structure design, forced air cooling and water cooling structure which can be upgraded and exchanged; Convenient and fast maintenance; Cooling area temperature display is adjustable.

Modular structure, easy to clean and maintain. Front and rear air return design, effectively prevent the influence of air flow between the zones, ensure accurate temperature control. Long life high performance hot air motor. Frequency converter control, wind speed adjustable hot air motor.

High-precision nitrogen flow agent and oxygen content analyzer can accurately control the nitrogen flow, and can be equipped with a nitrogen closed-loop control system to achieve low nitrogen consumption and low-cost production.

Option: full nitrogen filling Full nitrogen filling is optional, multi-directional protection product welding quality,to improve production efficiency.

Online maintenance rosin recovery system, simple operation, convenient and fast, effectively reduce customer production costs.

| SE series reflow oven main specifications (Daul Rails) | |||||||||

| Model No | YSL-708AHSE Daul Rails | YSL-708HSE Daul Rails | YSL-708NHSE Daul Rails | YSL-710AHSE Daul Rails | YSL-710HSE Daul Rails | YSL-710NHSE Daul Rails | YSL-712AHSE Daul Rails | YSL-712HSE Daul Rails | YSL-712NHSE Daul Rails |

| Heating System | |||||||||

| Heating Zone | 8 heating zones, 16 heating modules | 10 heating zones, 20 heating modules | 12 heating zones, 24 heating modules | ||||||

| Heating Length | 2950mm | 3670mm | 4350mm | ||||||

| Cooling Type | Double cooling:enforced air cooling/water cooling(Optional:three cooling zones) | ||||||||

| Outlet Exhaust Diameter valume | 2-145,Exhaust demand 15m³/min*2 | ||||||||

| Conveyor System | |||||||||

| Product width | Min50mm-Max270mm(simultaneously)/(Optional:Simultaneous overboard max300mm) | ||||||||

| Min50mm-Max500mm(single track)/(Optional: single track over board max550mm) | |||||||||

| Conveying Direction | L→R,R→L | ||||||||

| Inlet Height | 900±20mm | ||||||||

| Fixed Rail Side | Front and Rear End Rails Fixed,2 Central Rail adjustable | ||||||||

| Conveyor Type | Chain+mesh belt synchronous transmission | ||||||||

| Cmponent Height | Clearance based on the rail:above 30mm,below 20mm | ||||||||

| Conveying speed | 300mm-1500mm/min(Option:Double Speed) | ||||||||

| Control System | |||||||||

| Power Supply | AC3 5W 380V 50/60Hz | ||||||||

| Total Power | 70KW | 89KW | 108KW | ||||||

| Start Up Power | 35KW | 40KW | 42KW | ||||||

| Running Power | 10KW | 11.5KW | 13KW | ||||||

| Temperature Range | Room temperature to 320℃ | ||||||||

| Control type | PC+PLC Control system | ||||||||

| Rail Width Adjusting Mode | Electric+Manual | ||||||||

| Temp Control accuracy | ±1℃ | ||||||||

| PCB Temp Deviation | ±2℃ | ||||||||

| Data Storage | Process Data and status stotage | ||||||||

| Power Outage Protection | Equipped with UPS | ||||||||

| Operation interface | Windows Chinese simplified,English online free switching | ||||||||

| General | |||||||||

| Dimension(L*W*H) | 5055*1610*1515mm | 5775*1610*1515mm | 6495*1610*1515mm | ||||||

| Weight | 2500-2700KG | 2900-3100KG | 3300-3500KG | ||||||

| Color | Bright wrinkled white | ||||||||

Manual+electric width adjustment structure design, equipped with emergency manual transmission structure in case of preventing PCB burned when power off.

Conveyor system:stable and reliable anti-deformation structure design.

Built-in temperature profile test function, virtual simulation function, save setting time.

Two cooling zones

Cooling system, new patented structure design, forced air cooling and water cooling structure which can be upgraded and exchanged; Convenient and fast maintenance; Cooling area temperature display is adjustable.

Modular structure, easy to clean and maintain. Front and rear air return design, effectively prevent the influence of air flow between the zones, ensure accurate temperature control. Long life high performance hot air motor. Frequency converter control, wind speed adjustable hot air motor.

High-precision nitrogen flow agent and oxygen content analyzer can accurately control the nitrogen flow, and can be equipped with a nitrogen closed-loop control system to achieve low nitrogen consumption and low-cost production.

Option: full nitrogen filling Full nitrogen filling is optional, multi-directional protection product welding quality,to improve production efficiency.

Online maintenance rosin recovery system, simple operation, convenient and fast, effectively reduce customer production costs.

SMT placement machine placement machine parts placement machine

Dual arm magnetic linear LED highspeed pick and place machine

SMT Machine/ High Professional Customization/ Multi Function SMT Line Automatic Factory in China

Best Selling Heller Reflow Soldering Oven Machine For SMT Machine Line

High Speed 6 Heads Multi-functional SMT Pick and Place Machine LED Automatic

Contacts:Eva Liu +8613450659407 +86 13416743702

Tel:+86-512-62751429

Skype:evaliuhuan

Email: caojun@hk-yush.com sales@yushunli.com evaliu@hk-yush.com

Address: Building H, GuoRui Pioneering Park,

No. 1068 Jinyang East Road, Lujia Town, Kunshan,

Suzhou.

Postcode:215331

Dongguan Factory Address: 5th Floor, No.10, Shanquan Road,

Yongtou Village, Chang’an Town, Dongguan City, Guangdong

province,

China.

Postcode:523843