YSL-9 automatic vision printing machine is mainly used in mini LED, semiconductor printing, smart phone fields, Smart wear,can perfectly meet the fine pitch of 03015, 0.15Pich, and high precision requirements.

Technical Parameters

Screen Frames

| Min Size | 420x370MM |

| Max Size | 737X737MM |

| Thickness | 20-40MM |

| Stencil Position Mode | Automatic Y-axis positioning |

PCB Board Parameters

| PCB Min Size | 50x50mm |

| PCB Max Size | 510x340mm |

| PCB Thickness | 0.4-6mm |

| PCB Warpage | <1% |

| Image Capture Mechanical Range | 530x340mm |

| PCB Board Edge Clearance | 2.5mm |

| Board Height | 25mm |

| Transport Height | 900±40mm |

| Transport Speed | Max 1500mm/SProgrammable |

| Transport Mode | One section transportation track |

| Maximum PCB Board Weight | 5kg |

| Transport Direction | Left-Right; Right-Left; Left-Left; Right-Right |

Printing Parameters

| Printing Speed | 10-200mm/sec |

| Printing Pressure | 0.5-25kg |

| Printing Mode | Single or double squeegee printing |

| Release Distance | 0-20mm |

| Snap-Mode | Three stage demolding |

| Squeegee Angle | 60°/55°/45° |

| Squeegee Type | Rubber squeegee/Steel squeegee (Angle 45°/55°/60°) |

| Release Speed | 0-20mm/sec |

Printing Accuracy

| Repeat Position Accuracy | ±0.009mm@6o,CPK≥2.0 |

| Printing Accuracy | ±0.017mm@6 o,CPK≥2.0 |

| Cycle Time(Excluding Cleaning) | <7s (Exclude Printing&Cleaning ) |

| Cycle Time(Including Cleaning) | 13s |

| Changeover Time | 5Min |

Cleaning Parameters

| Cleaning Stroke | Automatic generation |

| Cleaning Position | Post cleaning(BTBpre cleaning) |

| Cleaning Speed | 10~200mm/sec |

| Cleaning Fluid Consumption | Auto&Manually adjustable |

| Cleaning Paper Consumption | Auto&Manually adjustable |

Image Parameters

| CCD FOV | 10*8mm |

| Camera Type | 130 megapixel digital camera |

| Camera System | Lock up/down iption structure |

| Camera Cycle Time | 150ms |

| Mark size | 0.1~6mm |

| Stay Away Number | Max:1pcs |

| Mark Number | Max:4pcs |

| 2D Detection | Detect low tin/missing print/continuous tin |

Functional Configuration

| Safely Control | Door open to stop, abnormal alarm |

| Smart UI | Brand new interface, shortcut key operation |

| Permission Setting | It can be freely set, and the authority division of operators,technicians and engineers can be set |

| BTB | Electrical cleaning layout is advanced, equipment is integrated, saving space and improving efficiency |

| Standard MES System | Customized output of Industry 4.0 solutions,can record SOP and equipment open data, and upload |

| SPI Connection | Automatic compensation for offset and detection of less tin,Automatic cleaning of steel mesh |

| Traceability System | Camera scan code, size compatible: 2.5*2.5-8.*8mm |

| In Series | Two machines are printed in tandem to increase productivity |

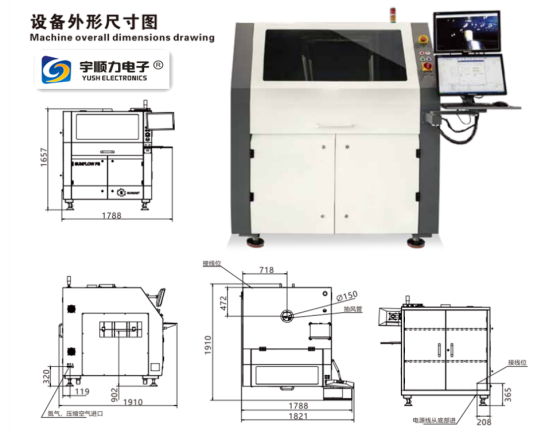

Appearance dimensions diagram

Installation equipment on-site matching

| Machine Weight | 1100kg |

| Main Power Supply | AC:220±10v;50/60Hz,3KW,with stable current and power supply |

| Ground Wire | The equipment needs to be grounded separately by pulling a grounding wire |

| Plug Type | English SS145(13A) |

| Main Air Supply Source | 4.0-6qf/cm?industrial gas source, with a straight airway diameter of 8mm |

Equipment operating environment

| Working Temperature | -20℃-45℃ |

| Working Environment Humidity | 30%~60% |

| Electrostatic Protection | ESD grounding electrostatic protection |

YSL-9 automatic vision printing machine is mainly used in mini LED, semiconductor printing, smart phone fields, Smart wear,can perfectly meet the fine pitch of 03015, 0.15Pich, and high precision requirements.

Technical Parameters

Screen Frames

| Min Size | 420x370MM |

| Max Size | 737X737MM |

| Thickness | 20-40MM |

| Stencil Position Mode | Automatic Y-axis positioning |

PCB Board Parameters

| PCB Min Size | 50x50mm |

| PCB Max Size | 510x340mm |

| PCB Thickness | 0.4-6mm |

| PCB Warpage | <1% |

| Image Capture Mechanical Range | 530x340mm |

| PCB Board Edge Clearance | 2.5mm |

| Board Height | 25mm |

| Transport Height | 900±40mm |

| Transport Speed | Max 1500mm/SProgrammable |

| Transport Mode | One section transportation track |

| Maximum PCB Board Weight | 5kg |

| Transport Direction | Left-Right; Right-Left; Left-Left; Right-Right |

Printing Parameters

| Printing Speed | 10-200mm/sec |

| Printing Pressure | 0.5-25kg |

| Printing Mode | Single or double squeegee printing |

| Release Distance | 0-20mm |

| Snap-Mode | Three stage demolding |

| Squeegee Angle | 60°/55°/45° |

| Squeegee Type | Rubber squeegee/Steel squeegee (Angle 45°/55°/60°) |

| Release Speed | 0-20mm/sec |

Printing Accuracy

| Repeat Position Accuracy | ±0.009mm@6o,CPK≥2.0 |

| Printing Accuracy | ±0.017mm@6 o,CPK≥2.0 |

| Cycle Time(Excluding Cleaning) | <7s (Exclude Printing&Cleaning ) |

| Cycle Time(Including Cleaning) | 13s |

| Changeover Time | 5Min |

Cleaning Parameters

| Cleaning Stroke | Automatic generation |

| Cleaning Position | Post cleaning(BTBpre cleaning) |

| Cleaning Speed | 10~200mm/sec |

| Cleaning Fluid Consumption | Auto&Manually adjustable |

| Cleaning Paper Consumption | Auto&Manually adjustable |

Image Parameters

| CCD FOV | 10*8mm |

| Camera Type | 130 megapixel digital camera |

| Camera System | Lock up/down iption structure |

| Camera Cycle Time | 150ms |

| Mark size | 0.1~6mm |

| Stay Away Number | Max:1pcs |

| Mark Number | Max:4pcs |

| 2D Detection | Detect low tin/missing print/continuous tin |

Functional Configuration

| Safely Control | Door open to stop, abnormal alarm |

| Smart UI | Brand new interface, shortcut key operation |

| Permission Setting | It can be freely set, and the authority division of operators,technicians and engineers can be set |

| BTB | Electrical cleaning layout is advanced, equipment is integrated, saving space and improving efficiency |

| Standard MES System | Customized output of Industry 4.0 solutions,can record SOP and equipment open data, and upload |

| SPI Connection | Automatic compensation for offset and detection of less tin,Automatic cleaning of steel mesh |

| Traceability System | Camera scan code, size compatible: 2.5*2.5-8.*8mm |

| In Series | Two machines are printed in tandem to increase productivity |

Appearance dimensions diagram

Installation equipment on-site matching

| Machine Weight | 1100kg |

| Main Power Supply | AC:220±10v;50/60Hz,3KW,with stable current and power supply |

| Ground Wire | The equipment needs to be grounded separately by pulling a grounding wire |

| Plug Type | English SS145(13A) |

| Main Air Supply Source | 4.0-6qf/cm?industrial gas source, with a straight airway diameter of 8mm |

Equipment operating environment

| Working Temperature | -20℃-45℃ |

| Working Environment Humidity | 30%~60% |

| Electrostatic Protection | ESD grounding electrostatic protection |

SMT placement machine placement machine parts placement machine

Dual arm magnetic linear LED highspeed pick and place machine

SMT Machine/ High Professional Customization/ Multi Function SMT Line Automatic Factory in China

Best Selling Heller Reflow Soldering Oven Machine For SMT Machine Line

High Speed 6 Heads Multi-functional SMT Pick and Place Machine LED Automatic

Contacts:Eva Liu +8613450659407 +86 13416743702

Tel:+86-512-62751429

Skype:evaliuhuan

Email: caojun@hk-yush.com sales@yushunli.com evaliu@hk-yush.com

Address: Building H, GuoRui Pioneering Park,

No. 1068 Jinyang East Road, Lujia Town, Kunshan,

Suzhou.

Postcode:215331

Dongguan Factory Address: 5th Floor, No.10, Shanquan Road,

Yongtou Village, Chang’an Town, Dongguan City, Guangdong

province,

China.

Postcode:523843