2. PLC control system.

3. Light touch LED membrane switch or touch screen control panel options available.

4. Top and bottom pneumatic clamps to secure magazine rack.

5.Pressure regulated on pusher’s to prevent board damage.

6. Self diagnostic error code display.

7. SMEMA compatible.

Aluminum Unloader LED circuit board with SMD components-YS-4533-X Specification parameter:

| Model | YS-3525-X | YS-4533-X | YS-539-X | YS-3546-X |

| PCB size(L*W) | 50*50-350*250 | 50*50-460*330 | 50*50-530*390 | 50*50-530*460 |

| Dimension(L*W*H) | 1730*770*1250 | 1900*850*1250 | 2330*910*1250 | 2330*980*1250 |

| Magazine size(L*W*H) | 355*320*563 | 460*400*563 | 535*460*570 | 535*530*570 |

| Weight (kg) | 165kg | 205kg | 225kg | 245kg |

| Step pitch select | 1-4(10mm step pitches) |

| Description | This equipment is used to collect PCBs into magazine at the end of SMT production line. |

| PCB loading time | Approx.5 seconds |

| Magazine change over time | Approx.25 seconds |

| Power source & consumption | 100-230VAC(customized),1ph,max 300VA |

| Magazine number | Transport up:1pcs,Transport down:1pcs(or customized) |

| PCB thickness(mm) | min 0.4mm |

| Transport direction | L→R or R→L |

| Transport height(mm) | 900±20(or customized) |

| Air pressure & consumption | 4-6bar,max 10L/min. |

2. PLC control system.

3. Light touch LED membrane switch or touch screen control panel options available.

4. Top and bottom pneumatic clamps to secure magazine rack.

5.Pressure regulated on pusher’s to prevent board damage.

6. Self diagnostic error code display.

7. SMEMA compatible.

Aluminum Unloader LED circuit board with SMD components-YS-4533-X Specification parameter:

| Model | YS-3525-X | YS-4533-X | YS-539-X | YS-3546-X |

| PCB size(L*W) | 50*50-350*250 | 50*50-460*330 | 50*50-530*390 | 50*50-530*460 |

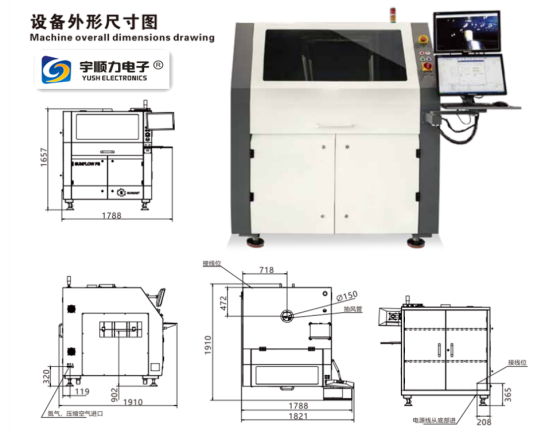

| Dimension(L*W*H) | 1730*770*1250 | 1900*850*1250 | 2330*910*1250 | 2330*980*1250 |

| Magazine size(L*W*H) | 355*320*563 | 460*400*563 | 535*460*570 | 535*530*570 |

| Weight (kg) | 165kg | 205kg | 225kg | 245kg |

| Step pitch select | 1-4(10mm step pitches) |

| Description | This equipment is used to collect PCBs into magazine at the end of SMT production line. |

| PCB loading time | Approx.5 seconds |

| Magazine change over time | Approx.25 seconds |

| Power source & consumption | 100-230VAC(customized),1ph,max 300VA |

| Magazine number | Transport up:1pcs,Transport down:1pcs(or customized) |

| PCB thickness(mm) | min 0.4mm |

| Transport direction | L→R or R→L |

| Transport height(mm) | 900±20(or customized) |

| Air pressure & consumption | 4-6bar,max 10L/min. |

SMT placement machine placement machine parts placement machine

Dual arm magnetic linear LED highspeed pick and place machine

SMT Machine/ High Professional Customization/ Multi Function SMT Line Automatic Factory in China

Best Selling Heller Reflow Soldering Oven Machine For SMT Machine Line

High Speed 6 Heads Multi-functional SMT Pick and Place Machine LED Automatic

Contacts:Eva Liu +8613450659407 +86 13416743702

Tel:+86-512-62751429

Skype:evaliuhuan

Email: caojun@hk-yush.com sales@yushunli.com evaliu@hk-yush.com

Address: Building H, GuoRui Pioneering Park,

No. 1068 Jinyang East Road, Lujia Town, Kunshan,

Suzhou.

Postcode:215331

Dongguan Factory Address: 5th Floor, No.10, Shanquan Road,

Yongtou Village, Chang’an Town, Dongguan City, Guangdong

province,

China.

Postcode:523843